Industry 4.0 is changing how factories and machines work, but keeping up with the right components is hard. More smart systems and connected devices mean that choosing the right technology is important to stay ahead.

The problem? Most businesses know which components are in high demand or which components help with automation and data processing.

This article will make it easy for you. You know what drives Industry 4.0 and IIoT: microcontrollers and connectivity modules.

You may be upgrading equipment or planning for the future - this guide can help.

We'll get started.

The Future of Industry 4.0 and IIoT

Advanced components are always needed as industries get smarter. Industry 4.0 and the Industrial Internet of Things (IIoT) - from automation to real-time data processing - rely on cutting-edge technologies to increase efficiency, decrease downtime, and optimize operations. They invest in components for faster communications, intelligent decision-making, and integration across industrial systems.

Driving this demand is the trend towards autonomous and data-driven manufacturing. Factories now have AI-powered microcontrollers (MCUs), high-speed connectivity modules, and smart sensors to communicate, analyze data and make real-time adjustments. Edge computing solutions are also becoming necessary, reducing cloud processing and handling data locally.

As energy efficiency and cybersecurity are priorities for industries, components such as industrial-grade SSDs and power management ICs (PMICs) are in high adoption. They assure secure data storage, efficient power use, and robust system performance in harsh conditions.

Technology will only increase demand for these components. Those that embrace these innovations will stay ahead of the curve in Industry 4.0 and improve productivity and prepare for the future.

1. Microcontrollers (MCUs): The Brains Behind Automation

Microcontrollers (MCUs) are crucial components of embedded systems, being tiny processors that govern functions in industrial equipment. Their efficiency, coupled with their ability to perform various functions, makes them crucial components in the modern industrial setting.

.png)

Factors Driving MCU Demand

● Edge Computing: Since real time data processing is required, MCUs allow localized computation, reduce latency and improve decision making.

● Energy Efficiency: Today's MCUs are low power and thus suitable for battery-operated IIoT devices.

● Integration of Artificial Intelligence: Advanced MCUs include AI capabilities for predictive analytics & smarter automation.

● Enhanced Security Features: With cybersecurity as a prime concern, MCUs with built-in encryption and secure boot processes are in demand.

Applications for Industrial 4.0.

● Robotics: MCUs control robots for assembly and quality inspection tasks.

● Predictive Maintenance: Analyzing data from sensors, MCUs predict equipment failures enabling prompt maintenance and reducing downtime.

● Smart Sensors and Actuators: MCU processes inputs from different sensors for real-time adjustment of industrial processes.

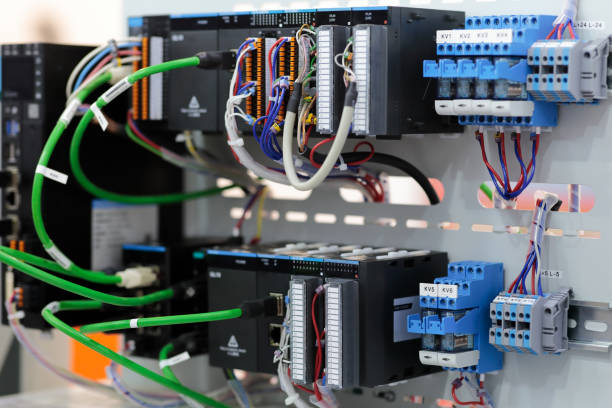

2. Connectivity Modules: Enabling Seamless Communication

Connectivity modules are the building blocks of IIoT, bridging devices across various networks. Their relevance stems from enabling continuous data exchange across systems.

Trends affecting Connectivity Module Demand

● Wireless Communication: This shift towards wireless systems demands modules that support Wi-Fi, Bluetooth, Zigbee and other wireless protocols.

● 5G Integration: High data transfer rates and low latency are reasons for industries to adopt 5G modules.

● Interoperability: Modules which interface with many protocols are needed for industrial setups.

Practical Applications

● Remote Monitoring: Connectivity modules permit real-time monitoring of equipment and fast response to anomalies.

● Supply Chain Optimization: More effective communications between devices help coordinate supply chain operations.

● Augmented Reality (AR) Support: Incorporating AR in maintenance and training requires robust connectivity solutions to overlay digital information onto physical equipment.

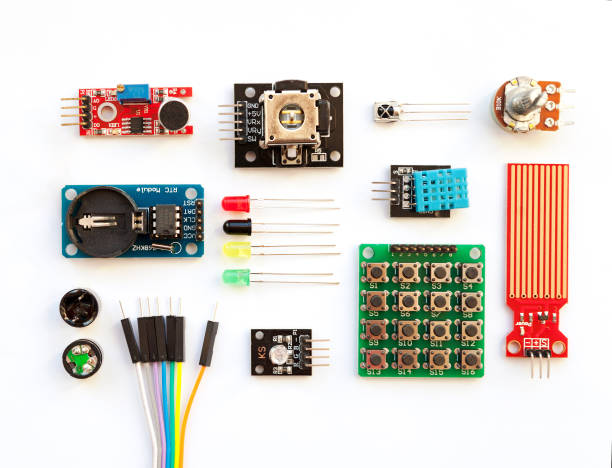

3. Sensors: The Eyes & Ears of Modern Industry

Sensors are crucial to gathering data from the environment, which is used to advise and optimize processes in industry.

Factors Leading to Increased Sensor Demand.

● Diverse Measurement Capabilities: Industry requires temperature, pressure, humidity and motion sensors.

● Miniaturization: Modern technology has made sensors smaller and can be fitted in compact and complex machinery.

● Cost Reduction: As sensor technology became more common, costs have dropped, and they can be deployed widely across operations.

Sensor Applications

● Environmental Monitoring: Environmental conditions in factories are monitored by sensors.

● Quality Control: Detected variations in production parameters maintain product quality and consistency.

● Energy Management: Energy consumption monitoring at the real-time level allows industries to save energy and cut costs.

4. Edge Computing Solutions: Processing Power At The Source

Edge computing means processing data near the source of generation, as opposed to relying solely on centralised cloud infrastructure. Edge computing has gained traction, particularly in industrial scenarios.

Reasons for the Edge Computing Surge.

● Latency Reduction: Processing the data on-site reduces delays - an important consideration in time sensitive applications like automated control systems.

● Bandwidth Optimization: Edge computing handles data locally and thus saves bandwidth by avoiding constant data transmission to central servers.

● Enhanced Data Security: Using local data processing reduces risks of sending sensitive information over networks.

Implementation in Industry

● Autonomous Machinery: Edge computing lets machines make instant decisions on real-time data.

● Real-Time Analytics: Industries process and analyze data instantly enabling proactive operation changes.

● Improved Reliability: Localised processing assures that critical functions work even when external networks are down.

5. Field-Programmable Gate Arrays (FPGAs): High-Performance Custom Processing

Field-Programmable Gate Arrays (FPGAs) are programmable semiconductor products that provide high processing performance coupled with concurrent computing, making them essential for both industrial automation and IIoT.

High-Performance Custom Processing.png)

Factors Driving FPGA Demand

● Real-Time Data Processing: FPGAs enable very fast computation in industrial control systems and predictive maintenance.

● Customizable Hardware Acceleration: FPGAs can be reprogrammed for specific industrial applications unlike standard processors.

● AI/Machine Learning Integration: Modern FPGAs enable AI-driven analytics, fault detection & anomaly detection.

● Energy Efficiency: Advanced FPGAs are low power devices suitable for IIoT edge devices.

Applications for Industrial 4.0.

● Robotics and Automation: FPGAs power robotic motion control & machine vision for precision manufacturing.

● Predictive Maintenance: They process live sensor data to detect patterns of possible machine failures.

● Smart Factory Networks: FPGAs improve industrial Ethernet and TSN performance in real-time communication.

6. Industrial-Grade Solid-State Drives (SSDs): Reliable Data Storage for IIoT

As factories compile, aggregate, and analyze vast quantities of sensor data, machine logs, and analytics, there exists an ever-increasing need for high-speed, reliable data storage. High performance, industrial-grade Solid-State Drives (SSDs) offer exceptional performance, coupled with exceptional longevity, well-suited for rigorous industrial application.

Reliable Data Storage for IIoT.png)

Factors Driving SSD Demand

● High-Speed Data Processing: Low latency storage is an essential requirement for real time IIoT analytics using SSDs.

● Rugged Durability: Industrial SSDs can withstand extreme temperatures, vibrations and power fluctuations unlike traditional hard drives.

● Secure Data Management: Some SSDs have encryption and secure erase features for industrial data protection.

● Edge Computing Integration: SSDs provide local data storage for autonomous systems/IIoT gateways without cloud dependency.

Applications for Industrial 4.0.

● Edge Devices 1 & 1: ioT Gateways: HDDs enable real-time data processing and machine learning models.

● Automated Production Systems: High speed SSDs allow continuous logging of machine performance data for production efficiency.

● Predictive Maintenance: SSDs hold historic sensor data for AI-based predictive failure analysis.

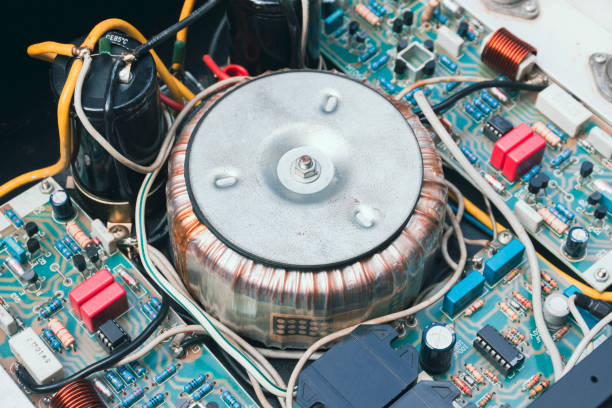

7. Power Management Integrated Circuits/PMICs: Efficient Energy Management

Power Management ICs (PMICs) actively take part in the management of power and in optimizing power efficiency in robots, industrial automation, and IIoT networks. With intelligent factories' pursuit of efficiency and green power, PMICs are taking a growing part.

Factors Driving PMIC Demand

● Low Power Consumption: PMICs reduce power waste making IIoT devices more energy efficient.

● Support for Renewable Energy: Intelligent factories including solar / wind / battery energy storage use advanced PMICs for optimal power management.

● Miniaturization 1and1 Integration: More recent PMICs are compact yet powerful and allow smaller, more compact industrial devices.

● Battery Life Extension: PMICs control battery-powered IIoT sensors and wireless industrial devices.

Applications for Industrial 4.0.

● Battery-Powered IIoT Sensors: PMICs support energy harvesting/power regulation extending sensor lifetime.

● Industrial Robotics 1and1 Automation: They distribute the power efficiently to ensure better robotic uptime and performance.

● Power Monitoring for Smart Grids: PMICs perform energy monitoring and load balancing in smart factory power grids.

Conclusion

Industry 4.0 and IIoT call for smart components such as MCUs, connectivity modules, sensors, edge computing, SSDs, and PMICs. They improve automation / data processing / energy efficiency.

It helps businesses increase productivity, reduce downtime, and remain competitive by adopting them. And on those innovations the future of smart factories depends - are you ready?

FAQs

1. In what ways do MCUs support AI-driven automation in Industry 4.0?

Modern MCUs incorporate AI features to enable real time data analysis / predictive maintenance / smarter decision making in industrial automation.

2. Which connectivity modules are involved in predictive maintenance?

Connectivity modules transmit live equipment data to monitoring systems for early detection of problems and reduced downtime of machines.

3. So why do sensors help in production efficiency?

Sensors gather temperature / pressure / motion data for automated process optimization and quality control systems.

4. How does edge computing enhance industrial cybersecurity?

As edge computing processes data locally, it removes the threat of cyberattacks on cloud-based networks for safe industrial operation.

5. What makes industrial-grade SSDs special?

Industrial SSDs resist heat, vibration and power fluctuations better than consumer SSDs.