- Introduction

1.1 What is an AC capacitor

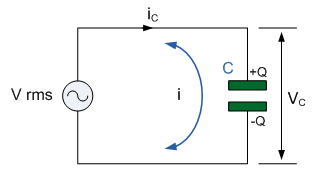

In our practical life and work, the vast majority of electrical equipment or household appliances, are using alternating current (AC), the power supply department grid to provide alternating current. For example, phase-shifting capacitors are used to improve the power factor of inductive loads, starting capacitors are used for single-phase asynchronous motors, and voltage-reducing capacitors are used in the silent remote operation of AC contactors. An AC capacitor is a type of capacitor designed primarily for use with industrial frequency AC voltages, which can be used in AC power supplies or DC power supplies with the same voltage as the AC RMS value of the capacitor's rated voltage.

figure 1: AC Capacitor Circuit

1.2 Why AC capacitors need to be tested.

As an important component in electronic equipment, AC capacitors play a vital role in the circuit. If the capacitor does not work properly, it will seriously affect the working stability of the whole circuit, causing various failures and errors in the equipment. By testing the capacitance value, current leakage and insulation resistance of capacitors and other indicators, it can be determined whether the capacitor is normal or not, and timely detection of faults and repairs can be carried out to ensure the stability of the circuit. Therefore, by testing AC appliances, the reliability of the equipment can be improved, the life of the equipment can be prolonged, the maintenance cost can be saved, and the production efficiency can be improved, etc.

Here is a video that can help you to tell if your AC Capacitor is bad or not.

How to tell if a AC Capacitor is Bad! Visual and Multimeter Testing!

2 Necessary tools

2.1 Introduction to the multimeter and its functions.

Multimeter, referred to as electric meter, is a fully functional, portable electric meter. It can be used to measure DC current, AC current resistance and other physical quantities, applied to the field of electronic testing, now on the market is mostly divided into analog and digital multimeter, analog multimeter is generally used as the core of the magnetic measurement, while the digital one is to use the voltage type of measurement. Multimeter is initially a combination of test equipment, used to determine the voltage, current, capacitance, resistance and some other measurements of any electrical device.

2.2 Safety measures for using the multimeter

Before each measurement, use the multimeter to check the position of the gear and gear switch. Although digital multimeters are protected against overvoltage and overcurrent, it is necessary to prevent damage to the instrument by misuse. For digital multimeters with automatic range selection, care should also be taken to use the eyelet switches and input jacks correctly. Do not touch the metal part of the probe when using it, so as to avoid electric shock accident and affect the measurement accuracy.

When measuring high voltage or high current, it is strictly forbidden to rotate the range switch to prevent arcing and burning of the switch contacts. When measuring voltage, it should be operated with one hand, i.e., first fix the black probe on the common terminal of the circuit under test, then hold the red probe to touch the test point to ensure safety.

When measuring in-line components on a circuit board, the effect of other components connected in parallel with them should be considered. If necessary, one end of the component under test should be soldered for measurement. For crystal transistors, two electrodes need to be soldered before testing. When measuring resistance in-line, operate with the power supply disconnected and note whether other components form a parallel circuit with the resistor under test. If necessary, solder one end of the circuit resistance before measurement. For circuits with electrolytic capacitors, energize the capacitor before measurement.

figure 2 A typical multimeter

- Step-by-Step Process

SAFETY FIRST: It is important to check that the capacitor is fully discharged before testing it, as it may be dangerous to connect a multimeter with a small charge in the capacitor. Make sure the capacitor is discharged. Capacitors can retain their charge for a period of time after the power is disconnected.

Disconnect the capacitor: Turn off the power and disconnect the capacitor from the circuit.

Setting the multimeter: Set your multimeter to the highest impedance range. The impedance function is usually indicated by the symbol for ohms .

Test the capacitor: Place the multimeter probes on the terminals of the capacitor. Connect the positive probe to the positive terminal and the negative probe to the negative terminal.

Record and interpret the reading: At first, the multimeter may show a low reading and then slowly rise. This is because the capacitor is charging. If the reading drops quickly, there may be a problem with the capacitor. If the reading stays steady, the capacitor is probably fine.

Please note that this is only a basic test and some complex problems may require specialized equipment and knowledge to solve. Please always observe safety regulations when testing capacitors.

Note:You may follow this this article to deepen your knowledge on how to test capacitors using a multimeter.

4. Common problems and solutions

The common failures of capacitors are: capacitor shell expansion or oil leakage; capacitor internal rattling; casing rupture, flash sparks; capacitor temperature abnormality. These are common failures of capacitors, if encountered should be dealt with immediately. The following are some common capacitor fault handling measures:

When the capacitor explodes on fire, immediately cut off the power supply and extinguish the fire with sand and a dry fire extinguisher.

Capacitor fault tripping, and the insurance is not fused, this time may be the line harmonic is too large, you can try to throw, if frequent tripping should be out of power maintenance, if necessary, you can increase the harmonic elimination device.

When the insurance fuse, need to first power off to check whether the capacitor is faulty, if the capacitor is normal, you can replace the fuse core after re-test casting, if it is still fused to carry out a comprehensive inspection, do not force the power supply.

In short, the capacitor has a short service life, should try to choose a good quality capacitor, to the life of the term should also be replaced in a timely manner. Daily maintenance, maintenance personnel should be familiar with capacitor troubleshooting measures, the capacitor as a key inspection program.

5 Conclusion

In summary, as one of the important components in electronic equipment, the purpose and significance of AC capacitor testing is very important. Regular capacitor testing can ensure the stability and reliability of the circuit, prolong the service life of the equipment and improve the production efficiency. At the same time, it is also necessary to pay attention to the detection methods and precautions, and in the process of capacitor testing, it is necessary to pay attention to safety issues to avoid dangers such as electric shock and electric shock. At the same time, it is also necessary to pay attention to the correctness of the detection method and the reliability of the test results, so as to find the capacitor failure in a timely manner, and to do a good job of repair and replacement and other work.