The automotive industry continues to revolutionize to cut off Greenhouse gas emissions and the use of fossil fuels. Embedded in this revolution is the pivotal point of power electronics. The automotive fast recovery Silicon Carbide (SiC) and Gallium Nitride (GaN) power devices emerge as game-changing technologies. These innovative wide-bandgap semiconductor materials are reshaping the sturdiness and effectiveness of the Electric Automobiles and improving the quality of the upcoming phase of eco-friendly transport.

Why SiC and GaN?

SiC (3.3eV) and GaN (3.4eV) are referred to as WBG semiconductors because they have superior electrical properties compared to conventional Si (1.1eV) based devices, as shown in Figure 1.

![]() Figure 1: Reliability of WBG semiconductors (SiC, GaN) compared to Si material properties summarized in a spider chart [1].

Figure 1: Reliability of WBG semiconductors (SiC, GaN) compared to Si material properties summarized in a spider chart [1].

Their exceptional benefits include:

1. Higher Breakdown Voltage: This enables operation at higher voltages desirable for EV power trains.

2. Faster Switching Speeds: Due to higher electron mobility, it enables almost 3x faster switching.

3. Higher Thermal Conductivity: Provides better heat dissipation and also enhanced reliability.

4. Compact Design: Use power electronics integration to minimize and lightweight power electronic components for lightweight EVs.

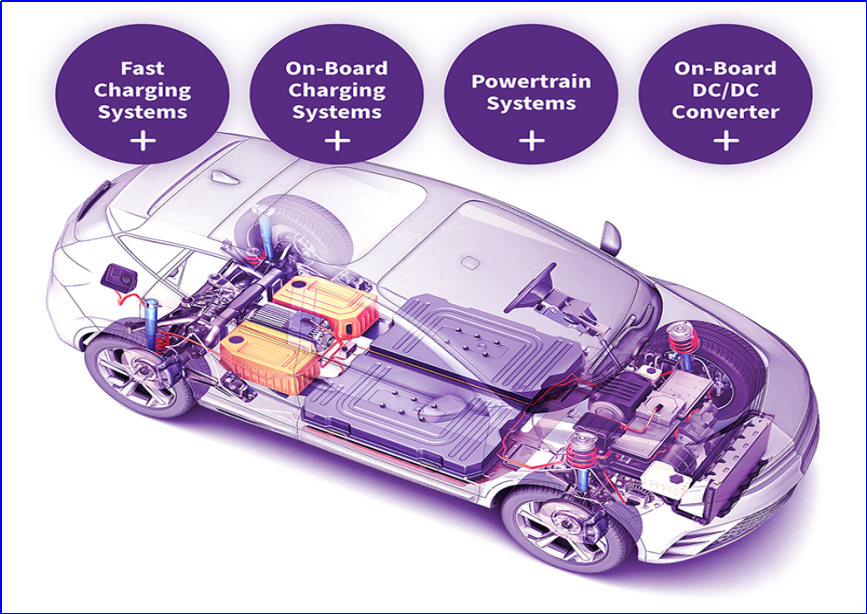

Critical Applications for Electric Vehicles

SiC and GaN devices are critical for the continuous growth of EVs since they provide better energy control, small size, and better heat dissipation. Each of them serves sundry functions within different types of EV systems, which are critical to efficiency and effectiveness. Here are some major applications given below:

1. Onboard Chargers (OBCs): SiC and GaN devices enhance the operation efficiency of OBCs since they reduce energy loss when converting AC to DC. This also makes the chargers compact and lightweight besides improving their performance through decreased size of the passive components that they use due to their high-frequency modulation.

2. Traction Inverters: Inverters are important for transforming direct current battery power to alternating current power for the electric motor. SiC inverters improve the overall efficiency and enable improved heat dissipation, which leads to higher energy density, and, as a result, increased driving ranges.

3. DC-DC Converter: Both Sic and GaN devices provide an added advantage because of their fast-switching characteristics and low energy dissipation.

4. Power train Electrification: SiC devices have been adopted in traction inverters and their use has greatly enhanced the performance of EV powertrains through the provision of better torque and acceleration rates.

Figure 2 shows the distribution and type of power electronics equipment that is involved in charging an EV, namely the onboard chargers, inverters and the DC-DC converter all connected by arrows illustrating the flow of power.

Figure 2: SiC and GaN Application in EV [2]

Specific Models of Automotive-Grade SiC/GaN Devices

To meet the growing demands of EVs, specific models of SiC and GaN power devices have been developed for automotive applications:

SiC Devices

1. Wolfspeed's C3M™ is a family of MOSFET characterized by high-density power and high reliability. These automotive-qualified devices are stated to have 20% lower switching losses with a 1200V rating than their predecessors, which has a direct impact on vehicle efficiency. It plays a vital role in traction inverters.

Figure 3: C3M0160120J

2. SCT3022KLHR is a SiC MOSFET with a trench structure, with a rating of 650V and 22A. It has low on-resistance and switching time. It is designed to enhance EV power train systems.

Figure 4: SCT3022KLHR

3. SCTW100N65G2V from STMicroelectronics, which can be found in traction inverters and onboard chargers, for its low switching losses and higher efficiency.

Figure 5: SCTW100N65G2V

4. ROHM SCT3030KR series has an advanced trench gate structure with a 750V rating and is very popular in the Asian market. These devices provide a good balance of performance and price, hence used by many Chinese manufacturers.

Figure 6: ROHM SCT3030KR

GaN Devices

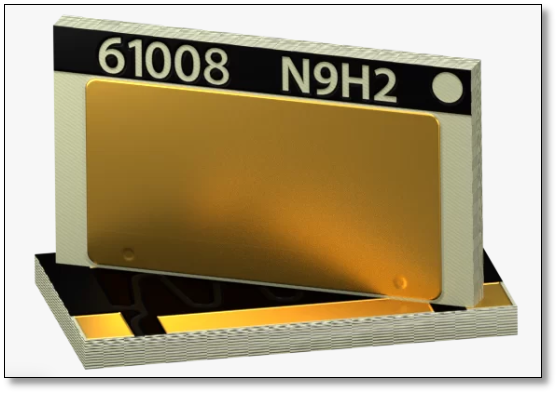

1. GaN Systems’ GS61008T is a reliable solution for DC-DC converters and onboard chargers because of high-switching speed.

Figure 7: GaN Systems’ GS61008T

2. The Infineon CoolGaN™ series 400V provides small and efficient solutions for the power train applications.

Figure 8: CoolGaN

You can directly check the Models mentioned above from the chart blow and buy or send a RFQ on JAK Electronics platform.

|

Category |

Product |

|

SiC |

|

|

SiC |

|

|

SiC |

|

|

GaN |

Challenges and Innovations

Challenges

· Manufacturing cost

· Limited supply

· Critical Manufacturing Process

Innovations

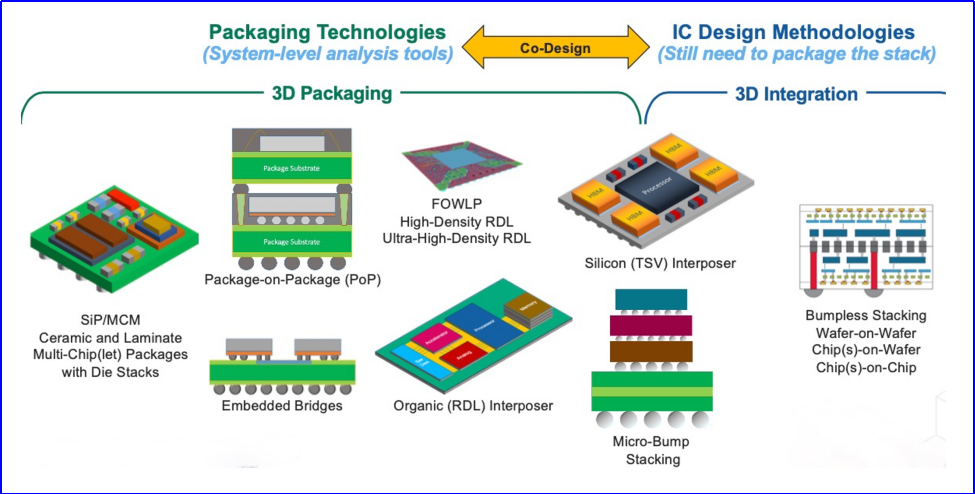

· Advanced Packaging: Modifying material thermal properties and minimizing packaging losses by doing bumpless stacking as shown in Figure 9.

· Manufacturing Improvements: Strengthening of material solutions and processes for SiC and GaN wafers, including growth of wafers at a lower cost and higher yield. Some notable investments are made for the manufacturer such as:

o Wolfspeed and ZF signed a deal to construct an 8-inch SiC fab in Germany.

o Infineon plans to spend US$2 billion building an 8-inch plant in Malaysia focused on SiC and GaN.

o Mitsubishi has planned to invest up to US$2B for SiC fab in Japan.

o Bosch will buy U.S. TSI and spend US$1.5 billion to update this plant for a SiC fab for the 8-inch process.

· Integration with Control Systems: Advanced package techniques to enhance forward and reverse conversion efficiency based on practical EV uses of WBG devices.

Figure 9: Advanced Packaging for Automotive Chips [3]

Market Outlook

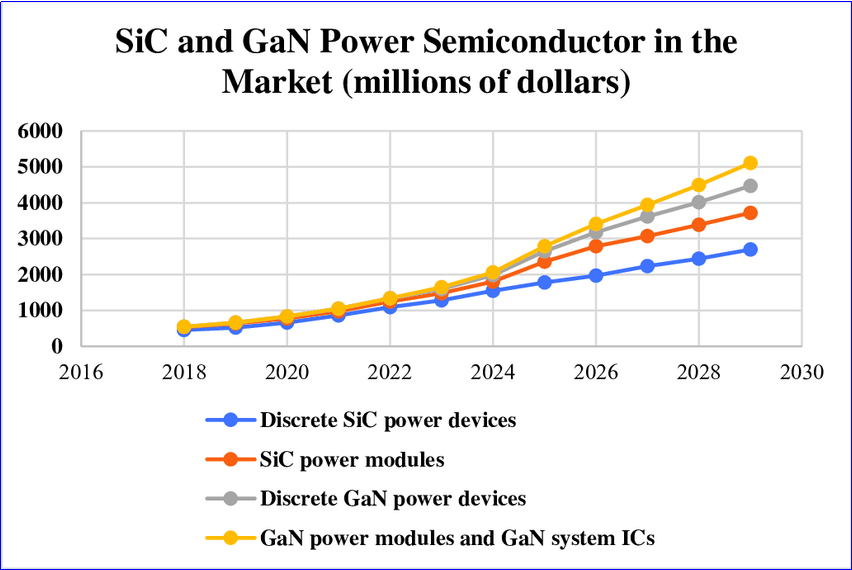

SiC and GaN power devices are gradually being used in EVs due to automobile companies like Tesla, Toyota, and Volkswagen’s push. Market data shows that the SiC power device market for EVs will rise dramatically, with GaN closely behind as production costs decrease further.

A forecast chart of market development indicating the use of SiC and GaN in EVs, categorized by Tesla and Toyota, is shown in Figure 10.

Figure 10: Graph depicts the exponential growth of the SIC and GaN device markets [4]

Emerging trends include

· Formation of multifunctional SiC/GaN power modules using multi-chip module technology.

· Emphasis on >1200V structures in Electrical vehicles since SiC devices provide a better result.

· Semiconductor firms provide pre-integrated solutions that can be customized for individual car models in collaboration between semiconductor firms and car makers for EVs.

Final Words

SiC and GaN power devices in automotive applications are no longer considered futuristic concepts – they are rapidly becoming mainstream components in today's electric vehicles. These WBG semiconductors are instrumental in transitioning the transportation sector to sustainable electrification through power electronic systems in terms of cost-effective operational efficiency, charging time, and range. As more innovations occur and cost reduces SiC and GaN will be the key components to take the EV industry into a cleaner and greener path. Consulting analysts forecast that over 50% of newly produced electric EVs will use either SiC or GaN power devices in their systems by 2026. This adoption rate is rising as the manufacturers understand the performance gains. Hence, SiC and Gan based EVs have promising future.

Reference

[1] L. A. Yeboah et al., “Exploring Innovations, Sustainability and Future Opportunities in Semiconductor Technologies,” Int. J. Adv. Nano Comput. Anal., vol. 3, no. 2, pp. 01–42, 2024.

[2] “Automotive Applications | SiC Power | Wolfspeed.” Accessed: Jan. 11, 2025. [Online]. Available: https://www.wolfspeed.com/applications/power/automotive/

[3] “Advanced Packaging For Automotive Chips.” Accessed: Jan. 11, 2025. [Online]. Available: https://semiengineering.com/advanced-packaging-for-automotive-chips/

[4] G. Rajendran, C. A. Vaithilingam, K. Naidu, K. S. Prakash, and M. R. Ahmed, “Hard switching characteristics of SiC and GaN devices for future electric vehicle charging stations,” in MATEC Web of Conferences, EDP Sciences, 2021, p. 02007. Accessed: Jan. 11, 2025. [Online]. Available: https://www.matec-conferences.org/articles/matecconf/abs/2021/04/matecconf_eureca2020_02007/matecconf_eureca2020_02007.html