Speed sensors are utilized to measure the speed at which devices are spinning. Many vehicles, including automobiles, aerospace vehicles, off-highway and construction equipment, railway vehicles, and military vehicles, require speed sensors.

If the speed sensor fails, the operation of the automatic gearbox will be adversely affected. The performance of an automatic gearbox that is not typical is one of the most common symptoms that a speed sensor is broken.

The transmission can display symptoms such as delayed shifts, harsh shifts, and limited gear operation if the VSS is malfunctioning.

This section will discuss types and functions of speed sensor, signs of bad speed sensor and how to test speed sensor .

Catalog

| Functions of Bad Speed Sensor |

| Speed Sensor Location |

| Types of Speed Sensors |

| Symptoms of a Bad Speed Sensor |

| How to Test a Speed Sensor? |

| How to Reset a Speed Sensor? |

| Conclusion |

Functions of Bad Speed Sensor

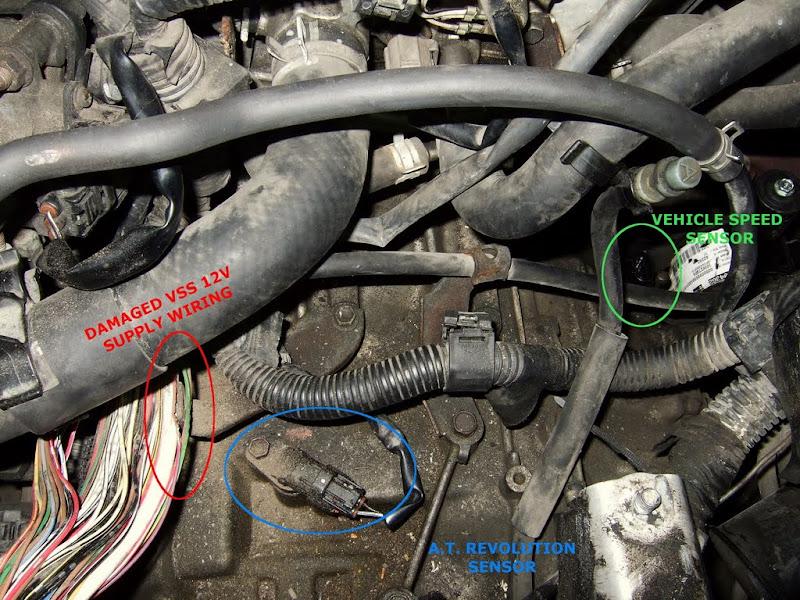

Figure 1. Functions of a bad speed sensor

The rotational speed of the gears in the transmission system may be determined with the help of the vehicle speed sensor . After the measurement has been determined, the data will either be transformed into an analog form or a low-voltage square wave signal.

After the movement has been successfully received, it is sent to the electronic control units within the car.

The electronic control units in the vehicle then make the necessary adjustments to the transmission system, ABS module, and speedometer readings based on the message received from the signal.

The cruise control system in a vehicle is controlled by signals transmitted by the vehicle speed sensor. A car must have these features to keep a consistent speed when driving. As a result, the speed sensor on the vehicle is an essential component.

Speed Sensor Location

Figure 2. Speed senor location

A transmission speed sensor is often located close to the transmission's output shaft. The Ford transmission speed sensor is placed to detect the post's rotation and speed. The attached cables can then convey this information to the engine computer.

Your car is equipped with sensors that constantly monitor the transmission speed. Altering the computer settings built into the engine might also help you achieve your desired level of performance.

The transmission pan is where speed sensors for BMW transmissions are located for both the output and input shafts of the gearbox. The sensor for the transmission input is closer to the front of the pan, while the sensor for the output is closer to the rear.

While some transfer cases only come with one sensor, others come with two. Both of them are going to be found on the back of the transfer case. Where they will be installed will be the tail shaft of the transfer case. If a piece of hardware has two sensors, one will be on the left and the other on the request.

The position of the speed sensor on the transmission may be found on the right-hand side. Examine the gadget to see if it has a plug-like component attached to the side. The length of the speed sensor is approximately 3 inches, and it terminates in an electrical connection that is plug-and-play.

Types of Speed Sensors

There are several types of speed sensors commonly used in various applications. Some of the most common types include:

Active Wheel Speed Sensors

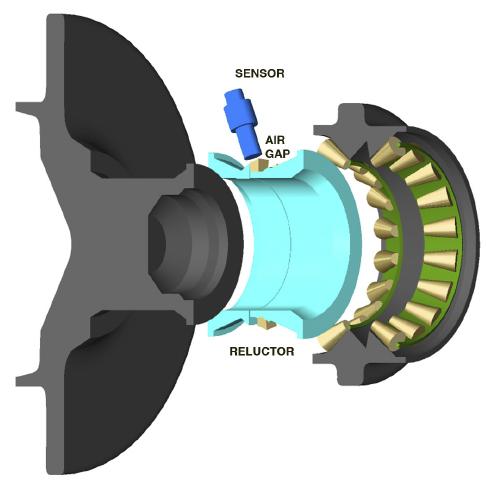

Figure 3. Active wheel speed sensors

Active wheel speed sensors, on the other hand, operate in a completely different manner than their passive counterparts, and this distinction is significant. The active wheel speed sensor is only considered "activated" when it is provided with a voltage and produces an output signal.

This is the only condition under which the term "activated" may be used. Because they feature a sensing element that is coupled to a magnetic element or a two-pole electric wire, active wheel speed sensors are also known as magneto-resistive sensors.

This is because the two types of sensors have the same characteristics. Because digital signals are more precise at low speeds and can determine the direction in which the wheel is rotating, an active sensor is more effective than a passive sensor.

Passive Wheel Speed Sensors

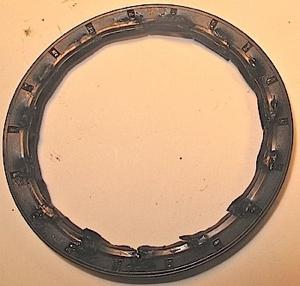

Figure 4. Passive wheel speed sensors

Passive speed sensors are also sometimes referred to as inductive or variable-reluctance magnet sensors. To function, these sensors do not need an external supply of voltage. It is on top of the impulse wheel, linked to the driving shaft below.

When the impulse wheel turns, the sensor determines the speed because there is a change in the winding from tooth to tooth, which causes a difference in the magnetic flow. This change in magnetic flow causes the sensor to determine the speed.

The passive sensor generates an alternating current signal that varies in frequency in response to the rate at which the wheel is rotating. This signal is then translated into a digital form.

Magnetoelectric Speed Sensor

This type of sensor uses changes in the magnetic field to detect vehicle speed. As the vehicle moves, the magnet on the wheel generates a rotating magnetic field, and the coil inside the sensor induces an electromotive force under the influence of the magnetic field, which is then converted into vehicle speed. These speed sensors are common in older vehicles; they are simple and reliable but not as precise as modern sensors.

Hall Effect Speed Sensor

Hall sensors work based on the Hall effect principle, measuring vehicle speed by detecting changes in the magnetic field. A magnet is placed on the wheel, and the Hall element inside the sensor generates a voltage difference under the influence of the magnetic field, which is proportional to the vehicle speed. Hall effect speed sensors are more accurate, resistant to dirt and moisture, and suitable for modern vehicles.

Photoelectric Speed Sensor

Photoelectric sensors use the photoelectric effect to measure vehicle speed. A light-blocking plate is placed on the wheel, and the photoelectric element inside the sensor generates a photocurrent under the influence of the light-blocking plate. The vehicle speed is calculated by measuring the frequency of the photocurrent. They are high-precision, resistant to magnetic interference, but may be affected by dirt and debris.

Variable Reluctance Speed Sensor (VR Sensor)

Variable reluctance speed sensors are non-contact sensors that use the magnetoresistive effect for conversion. They have high sensitivity, strong reliability, and fast response speed, but may not be as accurate as Hall effect sensors.

Piezoelectric Speed Sensor

Piezoelectric sensors are sensors that convert mechanical signals into electrical signals. They mainly achieve signal conversion by changing the piezoelectric effect of quartz crystals. Piezoelectric sensors have the advantages of high precision, high sensitivity, and high-frequency response. They are very durable and can provide accurate measurements but are more expensive than other types.

Symptoms of a Bad Speed Sensor

Figure 5. Symptoms of a bad speed sensor

When a speed sensor goes bad, it can lead to a variety of issues that affect the performance and safety of a vehicle. Here are some common symptoms and consequences of a faulty speed sensor:

Transmission Shifting Issues

The automatic shifting of a transmission is actually achieved by the high-pressure hydraulic oil in the hydraulic cylinder pushing a piston. When the speed sensor fails, the hydraulic oil cannot push the piston normally, leading to the transmission's inability to shift gears properly. Therefore, if the transmission cannot maintain normal operation, it indicates that there may be a problem with your speed accelerator.

Unreliable SpeedoMeter Reading

An irregular or erroneous reading on the speedometer is one of the most prevalent symptoms that the vehicle's speed sensor is malfunctioning, as we discussed before. If your speedometer is continuously leaping up and down or is not registering the right speed, there is a significant likelihood that the speed sensor in your vehicle is malfunctioning.

Increased Speed Uncertainty

If you notice that your vehicle hesitates when you try to accelerate, the problem may be caused by a defective speed sensor. Because a wide variety of other issues can bring on this symptom, it is essential to get your vehicle inspected by a professional technician as soon as possible.

Emerging Difficulties

The problem with your speed sensor is why you're having problems passing other vehicles on the highway. If the sensor is not operating as it should, the ECU cannot determine the appropriate quantity of gasoline to inject into the cylinders. Because of this, you will experience a decrease in power, and you won't be able to go around other vehicles.

The Warning Light for the Engine

The speed sensor may have an issue if the "check engine" light on your dashboard is illuminated.

Getting a diagnostic check done on your vehicle by a professional is the most reliable approach to obtaining this information. Most mechanics will be able to establish whether or not the troubles with your engine light are caused by a defective speed sensor.

When Idling, the Vehicle's Speed Decreases

If you have noticed that your vehicle's speed decreases while idling, there may be an issue with one or more of the sensors installed in your car.

Taking the vehicle to a mechanic for a diagnostic examination is likely to deliver the most authentic knowledge on the nature of the problem.

ABS System Failure or Traction Control Indicator Light On

The Anti-lock Braking System (ABS) and TCS system rely on speed sensor data to prevent wheel lock-up during braking and to maintain traction. A malfunction in the speed sensor can lead to the failure of the ABS function, causing the ABS system to be unable to accurately perceive wheel speed and slip conditions, which may result in wheel lock-up during emergency braking, significantly reducing the vehicle's braking safety. A malfunction in the TCS system may cause the drive wheels to slip easily on slippery road surfaces, affecting the vehicle's traction and stability. A faulty sensor can impair their effectiveness.

Cruise Control Not Available

The purpose of cruise control is to allow drivers to enjoy relaxed driving at a set speed. The cruise control system also depends on speed sensors to maintain the set vehicle speed. A sensor malfunction will directly lead to the cruise control function being unusable, affecting the comfort of long-distance driving.

symptoms of bad speed sensor ( the video from YouTube )

How to Test a Speed Sensor?

Figure 6. How to test a speed sensor

A vehicle speed sensor, or VSS for short, is a device that can determine the speed at which your vehicle is moving.

If the speedometer in your car suddenly stops working or fails to reflect the rate at which you are moving accurately, the problem most likely lies with the vehicle speed sensor (VSS).

You may use a multimeter to check your VSS's functionality and ensure that it operates as it should. To begin, disconnect and remove the vehicle speed sensor (VSS) from your engine so that you may test it.

After that, you may attach it to a multimeter and adjust it so that it reads alternating current (AC). Connect the VSS to a power drill so that you may replicate the rotation of the vehicle's transmission.

How to Reset a Speed Sensor?

Figure 7. How to reset a speed sensor

Speed sensor for an internal engine operates analogously to that of a magnet by switching on and off in response to the movement of the camshaft , it is impossible to harbor animosity toward one. You are free to use something else in its place.

The operation of a speed sensor is accomplished by having a draw activate or deactivate the sensor anytime a camshaft is in the immediate area. Before beginning the procedure, ensure that the speed sensor is appropriately fitted and that this step has been finished; the camshaft sensor will fit more easily once this step has been discontinued.

Because of a speed sensor, the engine's electronic circuit unit can always determine the precise position of the camshaft at any given time. As a consequence, it can ascertain which section of the valves will be responsible for which activities.

By synchronizing the timing, fuel is transferred to the cylinders and ignited at the right time. The movement of a camshaft affects the placement of fuel and exhaust valves.

Conclusion

Because of this, the transmission will not operate as it should. Either it will change more swiftly than anticipated or shift more roughly.

Another issue resulting from malfunctioning sensors is the scheduling of shifts, which increases the time between changes. When shifting becomes difficult, the transmission's internal components risk being destroyed.