Programmable logic controllers have become a moving force and a pivotal part of the modern industry, spanning from small, to medium to multinational industries. As part of factory automation and industrial process control, programmable logic controllers control a majority of applications and processes from simple lighting operations to controlling chemical processes that would otherwise be a difficult or near impossible task. In every essence, PLCs are designed to be a simple solution to all kinds of processes and manufacturing demands. Over the years they have grown to not only meet the demand but also to revolutionize the industry.

What is a PLC

Programmable logic controllers also known as PLCs are digital computers or microcontrollers designed as industrial-grade devices. To be more precise it can be described as an industrial, specialized embedded computer, usually with a rugged design to suit the environment it operates in. It is used to aid and perform control functions within manufacturing plants or process industries. Such functions include processing analogue and digital inputs, data conversion, interfacing with other devices using input and output interfaces and also offer various communication protocols.

Originally, they designed and developed to improve and completely replace electromechanical relay systems that were used in traditional systems. Modifying these systems often involved a lot of work, changing relays and rewiring new systems. With PLCs, the process is less complicated and labour-intensive. The user only needs to change the logic on the program and update it to the controller device, enabling them to control the logic in a matter of seconds. Thus offer a simpler, more convenient and more manageable solution when modifying the operations or installing a control system.

Most of the PLCs as well are modular, meaning that they can be assorted, arranged or customized depending on the user’s preference or need. These modules include discrete and analogue input and output modules, PID controls, motor controls, extension cards, serial communication modules, Human-Machine Interfaces (HMI), and high-speed networking interfaces among others. This makes PLC systems an easier option to manage, troubleshoot and maintain compared to traditional systems. PLCs over the years have also become quite affordable and easier to deal with, making them reliable, cost-effective and more versatile in application.

Although defined by the same defining features as microcontrollers and embedded controllers, programmable logic controllers have subtle differences that make them more robust and industrial-grade. As an electronic systems designer or engineer, oftentimes you will be faced with a choice between the three. It is important therefore to understand the similarities, and differences and when to choose PLCs. In this article, we will take a moment to compare and understand how a PLC differs from a microcontroller.

Understanding Programmable Logic Controllers

Any engineer that has worked in industrial setups is no stranger to PLCs and systems controlled by PLCs. Their applications range from production lines, road traffic signals, elevators, barriers and even HVAC systems. PLCs are capable of supporting various functions and can manipulate data whilst also supporting various protocols such as Modbus and Device Net. It is not uncommon as well to find microcontrollers and embedded controllers in place of PLCs. To understand PLCs, we need to understand the difference between embedded controllers and PLCs.

Defining a PLC

A programmable logic controller also known as a PLC, is a type of electronic gadget used to automate and regulate industrial operations. It is a customized computer that runs in real-time and is configured to keep track of inputs, make choices based on logic commands, and control outputs to carry out certain activities or functions. PLCs are frequently used to manage and optimize production processes in a variety of sectors, including manufacturing, automotive, energy, and process control.

Like other microcontrollers, PLCs will consist of one or several processor>processor>processor>processor cores with other peripherals that help the user interface with the chip such as memory, serial and parallel interfaces, and other I/O peripherals. At the most basic, they will be composed of a central processing unit (CPU), a power source, and input/output (I/O) modules. PLC programming is simpler than microcontroller coding. The PLC's CPU functions as its brain, carrying out preprogrammed commands and managing data flow. Sensor or other device signals are received by input modules, which then transform them into digital data the PLC can use. Based on the processed data, output modules direct actuators, motors, or other devices to carry out particular tasks.

Figure 1: Sample of Siemens PLCs

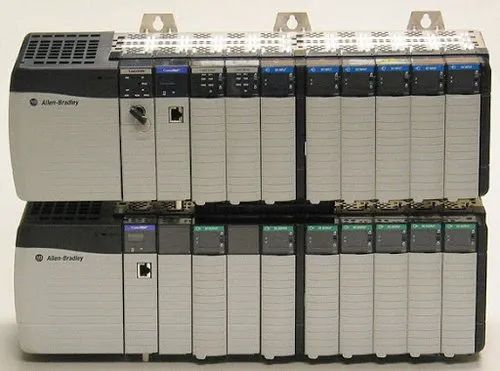

Figure 2: Allen Bradley PLCs

General-purpose microcontrollers or microprocessors are referred to as embedded controllers and are integrated into bigger systems or objects. They are designed in low-level languages like C or assembly language and conduct specialized system duties. Embedded controllers offer versatility in that they may be adapted to the needs of the system they are embedded in and are frequently tailored for particular applications. They may, however, differ in terms of industry standards and support and have restricted I/O capabilities.

PLCs, however, are specialized industrial controllers created for the real-time management and automation of industrial operations. They have user-friendly interfaces and support languages like ladder logic or structured text since they are programmed using specialized software. PLCs are stand-alone devices with flexible or fixed I/O configurations made to resist the abrasive conditions found in industrial settings. They are adaptable and flexible, making reprogramming and modification to meet shifting production needs simple. PLCs follow industry standards, guaranteeing their compatibility and interoperability. They also have access to a large network of vendors and experts that can help with support and maintenance.

Figure 3: Schneider Electric PLC

Basics of PLCs

Most of the PLCs similarly have common features including basic parts. Although they might vary in design, size and capability, the purpose and scope of the components and the units are the same. Therefore this makes it easier to understand PLCs and work conveniently regardless of the manufacturer, make or model of the PLCs.

Some of the basic parts of a PLC include a power supply, a microprocessor (CPU); a central processing unit, and output and output interface I/O ports or cards. PLCs are also designed with a rack, backplane or connector module that enables the PLCs to interface with the I/O modules.

The rack, which creates an electrical connection between each separate component, enables the PLC's modular design. An electrical connection contains both power and signalling data. Several PLC manufacturers utilize exclusive communication protocols on the backplane to provide a secure connection between I/O and the CPU.

- Power Supply

A PLC power supply is a crucial part of industrial automation systems that gives the programmable logic controller the required electrical power. It changes the input power source—typically mains electricity (240/120 VAC)—into a stable, regulated voltage that is appropriate for the PLC and the attached devices. The power supply delivers the necessary voltage and current capacity to the PLC, ensuring dependable and uninterrupted operation. To protect the PLC from electrical failures, it may have protective features like overvoltage and overcurrent protection. It is essential to choose a reliable PLC power supply to guarantee the durability and proper operation of the automation system.

Figure 4: Siemens PLC power supply unit

- CPU

The central processing unit, CPU are the most crucial part of the PLCs. It functions as the computer, the brains of the PLCS, it is responsible for taking the provided inputs and processing the required outputs depending on the instruction programmed.

- Modular I/O Card

The information in and out of the system is relayed through the input and output interface. The modular I/O cards attached to the PLCs are screwed to the I/O cards terminal and are used to exchange data with sensors, buttons, switches, relays, solenoids, and even networked devices. Depending on the requirements of each machine and facility, these cards can be selected.

Figure 5: A modular I/O card for Siemens PLC

Why PLCs

Programmable logic controllers are defined by their simplicity, inexpensiveness, flexibility, configurability and versatility in their different applications to meet diverse needs in the industrial sector. Since the 60s, when modern PLCs were introduced over the decades they have evolved and changed a great deal to meet the demands for higher performance, functional versatility and form factor. This has thus led to the redefinition of PLCs from simple controllers to near versatile industrial computers, capable of independent full function.

Here is a look at why PLCs are preferred over other microcontrollers in industrial applications:

1. Applications in Industry

PLCs are used in many different industries, including manufacturing, automotive, oil & gas, food processing, and more. They have improved control, monitoring, and data collecting, revolutionizing these industries. PLCs support overall operational excellence by enabling accurate process control, quality assurance, and effective production scheduling.

2. Versatility and Flexibility

When automating industrial processes, PLCs provide a great degree of variety and flexibility. They are simple to program and reprogram to fit a variety of activities and evolving production needs. They are appropriate for a variety of applications because of their versatility, from straightforward control duties to intricate automation systems.

3. Robustness and dependability

PLCs are made to work dependably in challenging industrial settings. They can survive harsh conditions such as high temperatures, vibrations, electrical noise, and other difficulties typically found in industrial settings. Increased productivity results from this reliability, which guarantees continuous performance and reduces downtime.

4. Diagnostics and troubleshooting

PLCs have powerful diagnostic features that help operators and maintenance staff locate and fix problems rapidly. System status indicators, error detection, and real-time monitoring allow for effective troubleshooting, which lowers downtime and enhances maintenance procedures.

5. Enhanced Safety Features

PLCs include built-in safety features that are essential in industrial settings. To safeguard people and equipment from potential risks, they support safety standards such as emergency stop features, interlocking mechanisms, and fail-safe operation.

6. Industry Standards and Support

PLCs follow well-established industry standards, guaranteeing compatibility and interoperability between various suppliers and systems. For PLC-based automation systems, there is also a broad network of suppliers, system integrators, and skilled individuals that may offer support, training, and maintenance services.

7. Scalability

To adapt to modifications in the production process, PLCs may be readily scaled up or down. The system's capacity can be increased by adding more input/output (I/O) modules, or its functionality can be reduced by removing modules that are no longer needed for a certain task. Because of this scalability, organizations may modify their automation systems as necessary without having to make large changes to their infrastructure.

8. Integration

PLCs have the ability to integrate with a wide range of components and systems, including sensors, drives, motors, HMIs, and other control systems. The effectiveness of the entire system is increased by the smooth communication and coordination that this interoperability enables across various components.

9. Programming Environment

The user-friendly programming environments found in PLCs make it easy to build and debug control logic in an effective manner. Control engineers and technicians are accustomed to programming languages like ladder logic, structured text, and function block diagrams that are frequently utilized.

10. Return on Investment and Cost reductions

Using PLCs in industrial settings frequently results in cost reductions. Through better resource management, they increase efficiency, optimize energy use, and lower operating expenses. PLCs also significantly increase productivity and decrease downtime, which boosts profitability and increases return on investment (ROI).

Future of PLCs

PLC technology is still developing, with new trends like cloud-based PLCs, edge computing, and Internet of Things (IoT) integration. These developments open up new possibilities for data analysis, automation, and remote monitoring, paving the way for more advanced control systems and preventive maintenance.

PLCs have generally had a significant impact on the industry by raising productivity, cost-effectiveness, efficiency, and safety. PLCs have become an indispensable part of contemporary industrial systems as a result of their integration into industrial processes, which have revolutionized production and automation.

Overall, PLCs provide an industrial automation system that is dependable, adaptable, and expandable. They are the favoured option in a variety of industries due to their capacity for managing complex activities, integrating with different devices, and offering solid performance. PLCs help industrial processes run more smoothly, productively, safely, and economically.