Solid state relay and electromechanical relays play different roles in the field of electrical control. When it comes to solving problems with circuit control or switch operation, some argue that solid-state relays are the future because they offer higher reliability, faster response times, and better electromagnetic compatibility, while others insist that electromechanical relays are more economical in some applications, especially in cost-sensitive applications.

To determine who is right, we need to delve into how these two relays work, their performance characteristics, and their application scenarios.

What is relay?

A Relay is an electrical device that acts as a switch in a circuit to help control the flow of current, transmit signals in the circuit, or control other devices. Just like switches in everyday life, relays allow the current in a circuit to be turned on or off when needed.

When we need to control some equipment or lights, etc., we can use relays to achieve it. For example, when we press a switch to control the lights in a room, we actually use relays to control the flow of electricity, so that the lights come on or go off.

Relays are like the switch assistants of the electronic world, helping us control various operations in the circuit, making automation and remote control easier.

Types of Relay

Relays can be broadly categorized into two main categories:

- solid state relay

- electromechanical relay

What is solid state relay

The electrical symbol of a solid state relay is SSR. A solid state relay is a special type of relay that uses semiconductor devices rather than mechanical parts to control the switching of a circuit. It uses semiconductor devices (such as thyristors or transistors) to control and transmit electrical signals, and has the advantages of fast response, long life and silence.

Solid State Relay (SSR) Circuit symbol

Solid state relay working principle

Solid-state relays work by controlling electrical signals at the input to drive internal semiconductor devices. When the input signal is applied to the relay, the semiconductor device will be switched on, connecting the load circuit; When the input signal stops, the semiconductor device will disconnect, cutting off the load circuit. In this way, the switch control of the circuit is realized. The working principle of solid-state relays is similar to that of traditional electromechanical relays, but there are no moving parts, which can effectively replace the application of traditional electromagnetic relays in many circuit controls, so it is more durable, faster, noiseless, and effectively improves the reliability and control effect of electrical equipment.

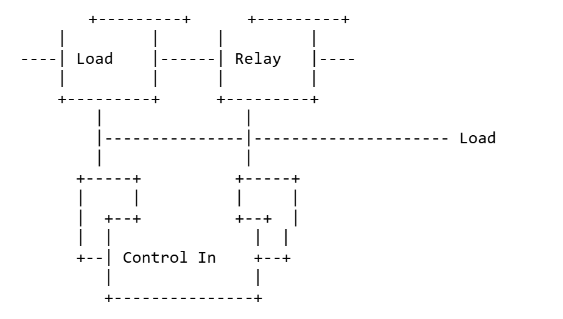

Here is an example of a common solid-state relay wiring diagram:

solid state relay wiring diagram

In the figure above, load is the load, relay is the solid-state relay, and control in is the control input. By adding the external control signal to the control in the end, the working state of the solid-state relay can be controlled, and the load can be controlled on and off.

What is a solid state relay used for?

At present, solid-state relays have been widely used in computer peripheral interface devices, electric furnace heating constant temperature systems, CNC machinery, remote control systems, industrial automation devices; Signal lamp, flicker, lighting stage lighting control system; Instruments, medical instruments, copiers, automatic washing machines; Automatic fire protection, security systems, as well as power capacitor switching switches as power grid power factor compensation, etc., in addition to chemical, coal mining and other explosion-proof, moisture-proof, anti-corrosion occasions are widely used.

What is electromechanical relay?

An electromagnetic relay is an electrical switching device that connects and disconnects circuits by using electromagnetic force to control the switching action. The main functions include isolation, amplification, switching and protection, which are widely used in power systems, industrial control, automotive electronics and home appliances.

Electromechanical relay working principle

The electromagnetic relay is actually a combined circuit, composed of coils, iron cores, contacts, etc. When the current passes through the coil, a magnetic field is generated, and the magnetic field acts on the iron core, making the contact close or break, thus achieving the conversion of the circuit signal. In the electromagnetic relay, the coil is the input end and the contact is the output end, which has the isolation function and can realize the isolation between different circuits.

Electromechanical relay applications

Electromagnetic relays are widely used in various electrical systems and control circuits, such as relay protection in power systems, logic control and switching in industrial control, signal control and load drive in automotive electronics, and power control and protection in household appliances.

Solid State Relay vs. Electromechanical Relay

Solid state relay and electromechanical relay are both devices that control circuit switches, but there are many differences between them. Here are some of their common differences:

|

Aspect |

Solid State Relay |

Electromechanical Relay |

|

Overview |

Contactless electronic relay |

Traditional mechanical relay |

|

Working principle |

Controls circuit switching using semiconductor devices |

Works based on electromagnetic principles, using mechanical contacts to control switching. |

|

Lifespan |

No mechanical parts, long lifespan |

Mechanical contacts prone to wear, leading to shorter lifespan |

|

Size |

Smaller and lighter, suitable for limited space or lightweight designs |

Larger and heavier due to mechanical structure |

|

Noise |

No mechanical contacts, silent operation |

Mechanical movement causes noise during operation |

|

Switching speed |

No mechanical contacts, high-speed switching |

Slower switching due to mechanical contacts |

|

Applications |

Suitable for precision instruments, automation, digital circuits |

Used for high current, high capacity circuit control in areas like automotive and industrial control |

|

Losses |

No mechanical movement, no mechanical heat losses |

Higher mechanical failure rate leads to mechanical heat losses |

|

Cost |

Higher due to semiconductor components |

Lower due to traditional mechanical structure (though additional measures like heat sinks and thermal grease may be needed for stable operation) |

|

Advantages |

High precision, fast response, reliable and long lifespan |

High reliability, high capacity for switching loads |

|

Disadvantages |

Limited switching capacity, not suitable for high capacity circuit control |

Issues like noise and high mechanical failure rates |

Summary

The working principle of an electromagnetic relay is relatively simple. When current flows through the electromagnetic coil, the coil generates a magnetic field that attracts the armature, thereby moving the contacts to make or break a connection. This mechanical action gives electromagnetic relays an advantage in certain applications, such as those requiring high-power control or high voltage.

However, electromagnetic relays also have some drawbacks. Due to their mechanical structure, they generate noise during switching and have a relatively short lifespan. Additionally, electromagnetic relays have slow response times, making them unsuitable for high-speed switching applications.

On the other hand, solid-state relays operate on a different principle. They utilize electronic components like optocouplers and thyristors to control the switching of circuits. Because they lack mechanical contacts, solid-state relays do not produce noise during switching and have a longer lifespan.

Solid-state relays offer additional advantages such as fast response times, strong immunity to interference, and compact size. This has led to their widespread use in many modern electronic systems, particularly in scenarios that require high-speed and high-frequency switching.

However, due to the characteristics of semiconductor devices, solid-state relays are limited by voltage and current constraints and are relatively costly.

In conclusion, both solid-state relays and electromagnetic relays have their own advantages and disadvantages, suitable for different scenarios. When selecting a relay, it is important to consider specific application requirements and environmental factors. Solid-state relays are suitable for applications needing fast response times, long lifespan, and noise-free operation, while electromagnetic relays are preferred for handling high currents and cost-effectiveness.

ALSO READ: Solid State vs. Electromechanical Relays

Are electromagnetic relays more reliable than solid-state relays when selecting relays?

Not necessarily, it needs to be considered from different angles. For scenarios requiring complex control logic, electromagnetic relays self-locking interlock is more convenient, adapt to complex control circuits, and have higher reliability than solid-state relays. However, the stability of solid-state relays is better, and it is suitable for use under harsh environmental conditions such as mines, gas and tunnels. The stability of the electromagnetic relay is relatively poor, the coil is easy to oxidize in a humid environment, and the frequent action contact has a certain wear.