1. Introduction

Invented by Boykin in 1959, resistors are today commonly used in almost all electronic circuits. Resistors can be described as a device that resists the flow of current flowing through itself, back when the resistor size was very huge and the tolerance value reached as high as 10 percent when it was implemented. Besides, they are usually made of compressed carbon. Resistors are mostly made from metal films and are available in small SMD packets with a tolerance value of as little as 2%, or even less, in the case of precision resistors. Carmet, KWK, Epcos India Pvt Ltd. and more are some of the leading manufacturers of resistors in India. If you didn't know, India accounts for some 34% of the market for passive components such as resistors by importing them, the remainder being imported.

If you are interested in learning more about the work and characteristics of resistors, then you can try reading this article. We will address the difference between carbon-film -and-metal-film-resistors>carbon film resistors and metal film resistors in this article.

2. Brief Intro to the Resistors

The word "resistor" is born from the word "resist," meaning to withstand the impact. A resistor resists the movement of electrons that move through it, guides it, or controls it. With the support of the conductive material that it is made of, this is achieved. Now, the name makes sense, does it not? In parallel and series, resistors are connected according to the specifications for current and voltage.

These small devices monitor, attenuate or decrease voltage and current, but do not have a power source of their own. The current flows through them in a controlled manner, resulting in a heat-like loss of energy. Only when there is a potential difference do two resistors bind and carry on a current between them. Yeah, they obey the Rule of Ohm. You must have heard, we're sure, of this statute. Oh, in the field of electronics and electrics, it is something to swear by.

Moving on, depending on their characteristics, there is an infinite list of various types of resistors including composition form, film type, and wire-wound type of resistors . Physical size, durability, temperature rating, noise, temperature coefficient, and voltage coefficient, to name a few of these features.

Well, the drill is known to you. We are here, however, to address two very significant types of resistors that are capable of transforming your electronic circuits.

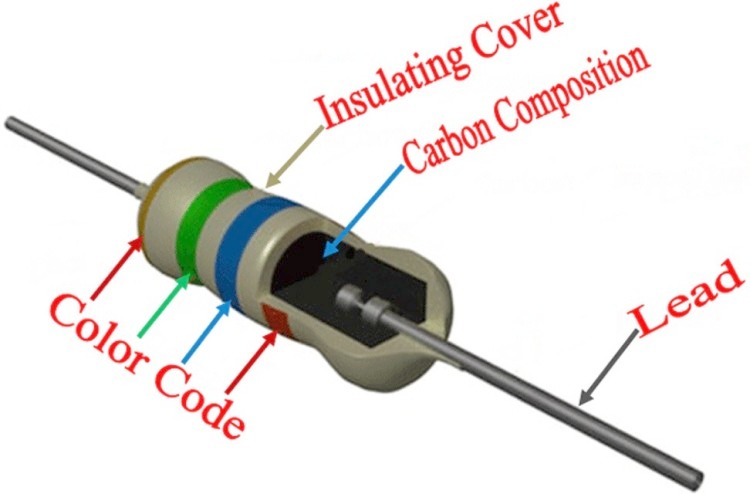

3. Carbon Film Resistors

Let us first contemplate what film resistors are before we begin talking about this. Well, after depositing oxide film or pure metals on a substrate or some insulating ceramic, these are simply those resistors that are formed. The layer is extremely thin and sputtering is known as the entire process.

By depositing carbon film on the ceramic substrate that is an insulator, the carbon film resistor is prepared. The electric current is blocked by the carbon film to a certain degree. The insulating ceramic, on the other hand, does not allow heat to move through it, which in turn allows the carbon film resistor to withstand massive temperatures without being harmed. Carbon film resistors have a good tolerance rating, available from 1 ohm to 1 megaohm.

Speaking of the resistance coefficient of negative temperature - the property of observing a decrease in resistance in response to a rise in temperature, these have a high coefficient of negative temperature that makes them susceptible to decreasing resistance as the temperature increases.

These resistors are also available and have a very low tolerance at a low cost. They have a large variety of activities. Carbon film resistor applications are commonly used in X-Rays, power supplies and RADAR.

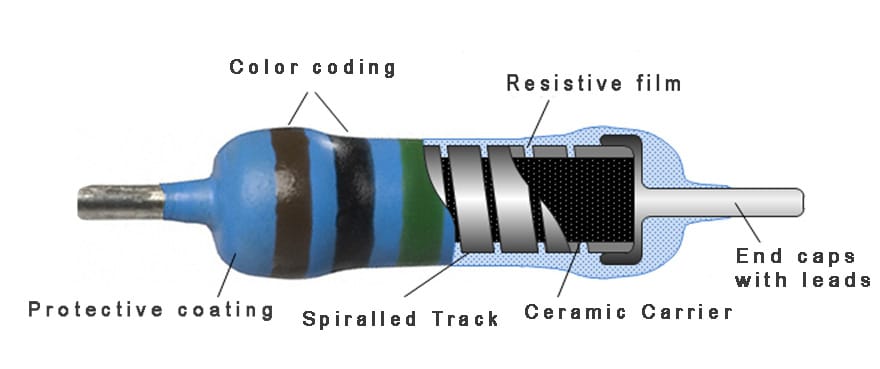

4. Metal Oxide Film Resistors

Metal oxide film resistors use thin metal oxide films to coat an insulating ceramic rod, in contrast to carbon film resistors. Informing a coating film, the compound made from oxygen atoms and other atoms performs wonders. Using tin oxide, however, metal oxide film resistors are made. To produce better resistance, antimony oxide is also added.

Because of the existence of an insulating ceramic rod that does not let heat pass through itself, these resistors are capable of withstanding high temperatures. Metal oxide resists the current at the same time. The greater the sum of antimony, the greater the resistance. But that doesn't even stop here, for good resistance metal oxide film resistors rely heavily on the thickness of the metal oxide and the width of the helical metal oxide film cut. The helical metal oxide film cut width and metal oxide thickness are inversely proportional to the resistance.

Wondering what makes them special? Resistors come at a very low cost and withstand high temperatures while making much less sound. Also, along with high reliability and stability, they are small in scale.

5. Carbon Film Resistor VS Metal Oxide Film Resistor

Well, engineers are still in a dilemma about which to use one. Whether to use the resistor for the carbon film or the resistor for the metal oxide film. All right, let us break it down, bit by bit, for you. You want your experiments, after all, to go spot on.

According to our contrast between Metal Film and Carbon Film Resistors, due to certain properties they possess that are listed below, we feel that metal-oxide film resistors prevail over carbon film resistors.

6. Voltage and Temperature Coefficient

There are a stronger voltage coefficient and temperature coefficient for Metal Oxide film resistors than for carbon film resistors. The coefficient of voltage is the change in resistance concerning the change in voltage. In short, it is the ratio of the resistance change to the voltage change. Metal oxide film resistors operate in a wide range of resistors and can withstand a higher temperature than the resistors of the carbon film.

Noise Design In contrast to carbon film resistors, metal oxide film resistors has a low noise design. They keep the minimum current. Therefore, it ensures less noise.

If you didn't know, metal oxide film resistors, relative to carbon film resistors, make up for stronger resistors for radio frequency or high-frequency applications. Tolerance The 2 percent minimum carbon film resistor tolerance level does not stand a chance against metal oxide film resistors that can go as low as 0.1 percent.

7. Size

Finally, compared to the carbon film resistors, the size of the metal oxide film resistors is smaller, making them a safer choice to go for. Now that we've done our bit to make you see the complexities of the resistors of both kinds, you can take your pick.