AC Fan Motors definition, types and working

Definition of AC fan motors

AC fan motors are electromechanical devices that convert electrical energy into mechanical energy to rotate the fan blades. They are commonly used in various HVAC (Heating, Ventilation, and Air Conditioning) applications, including condenser units, air handling units, and cooling towers. AC fan motors are electric motors specifically designed for driving fans in air conditioning and cooling systems.

Different types of AC fan motors

AC fan motors come in various types, each serving specific functions in air conditioning and cooling systems. Two common types of AC fan motors are condenser fan motors and blower motors.

Condenser Fan Motors:

Condenser fan motors are primarily used in the outdoor unit of air conditioning systems, known as the condenser unit. Their main purpose is to assist in heat dissipation by moving air across the condenser coil. Key features of condenser fan motors include:

Location: Condenser fan motors are typically located in the outdoor unit, mounted near the condenser coil and compressor.

Heat Dissipation: These motors facilitate the transfer of heat from the refrigerant to the surrounding air. They help maintain proper operating temperatures for efficient cooling.

Specifications: Condenser fan motors are designed to withstand outdoor conditions, including exposure to weather elements. They often have higher horsepower ratings compared to blower motors.

Blower Motors:

Blower motors are responsible for air circulation and ventilation within HVAC systems. They help distribute conditioned air throughout the space, ensuring proper airflow and comfort. Some key features of blower motors include:

Application: Blower motors are commonly found in air handling units, furnaces, and ventilation systems. They drive the fan blades that move air through ductwork and into different areas.

Air Circulation: Blower motors generate airflow, creating the necessary pressure to push air through filters, coils, and ducts. They play a crucial role in maintaining indoor air quality and temperature.

Types: Blower motors come in various types, including single-speed, multi-speed, electronically commutated motors (ECMs), and permanent split capacitor (PSC) motors. Each type offers different speed control and energy efficiency capabilities.

Also read: Symptoms of Bad Blower Motor Resistor & Replacement Cost

How AC fan motors work in cooling systems

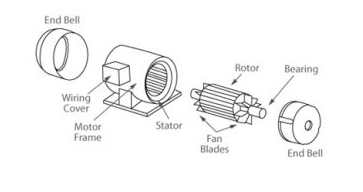

AC Fan Motor is mainly composed of two parts: electrical part and mechanical part. The electrical part includes components such as stator, rotor and winding, and the mechanical part includes components such as rotor shaft, blade and casing.

In terms of circuit, the AC fan motor is mainly composed of four parts, such as AC power supply, stator, rotor and winding. Among them, the winding on the stator is called the main winding, which is the core part of the motor. The rotor rotates through the interaction of an electromotive force and a magnetic field, causing the blades to generate wind energy, which is how the motor works.

Figure: Structure of AC Fan Motor

The working principle of the motor is based on the principle of electromagnetic induction. When the AC power supply is passed into the motor, a magnetic field is generated in the winding through the flow of electrons, which causes the interaction between the stator and the rotor to produce rotation. This is because the flow of electrons in the winding changes with time, which can produce magnetic field rotation. Under the influence of the AC power supply, the alternating magnetic field will constantly change the direction and size of the magnetic field, which drives the rotor to produce movement, and finally drives the fan blade to rotate.

Common Issues and how to fix

Signs of a bad AC fan motor: How to know if your AC fan motor is bad

Lack of Airflow: One of the first signs of a failing fan motor is a noticeable decrease in airflow from the vents. If you notice weak or reduced airflow even when the AC is running, it could indicate a problem with the fan motor.

Noisy Operation: A faulty fan motor can produce unusual sounds, such as grinding, squeaking, or rattling noises. These noises may indicate worn-out bearings, loose components, or motor imbalance.

Overheating: If the AC fan motor is struggling to operate efficiently, it may overheat. Excessive heat can cause the motor to shut down or trip the internal thermal overload protection, leading to intermittent cooling or complete system failure.

Inconsistent Cooling: A malfunctioning fan motor can result in inconsistent cooling throughout your space. You may notice areas that are not adequately cooled or persistent hot spots, indicating an issue with air circulation.

Frequent On/Off Cycling: If the fan motor is experiencing difficulties, it may cause the AC unit to cycle on and off more frequently than usual. This rapid cycling can strain the motor and lead to increased energy consumption.

Non-Responsive Fan: When the AC fan motor fails completely, the fan may not spin at all, even when the AC is turned on. This can result in no airflow or significantly reduced cooling capacity.

Common causes of AC fan motor failure

Lack of Maintenance: Inadequate maintenance, such as neglecting regular cleaning and lubrication, can lead to motor failure over time. Dust, debris, and dirt accumulation can hinder the motor's performance and cause it to overheat or become less efficient.

Electrical Problems: Electrical issues can contribute to fan motor failure. Some common electrical causes include:Voltage Fluctuations、Faulty Wiring or Connections、Capacitor Failure

Overheating: AC fan motors generate heat during operation, but excessive heat can lead to motor failure. Overheating can occur due to:Lack of Proper Ventilation, Dirty or Clogged Air Filters.

Age and Wear: Over time, the components of an AC fan motor can wear out, especially if the motor is older or has been subject to heavy usage. Bearings may become worn, windings may deteriorate, and the motor's overall performance can decline.

Environmental Factors: Environmental conditions can impact the lifespan of an AC fan motor. Factors such as exposure to extreme temperatures, moisture, corrosion, or contaminants in the air can contribute to motor failure.

Improper Sizing or Installation: If the fan motor is not properly sized or installed for the specific AC unit, it can cause strain, overheating, and premature failure

AC fan motor replacement: When and how to replace a faulty motor

Knowing when to replace a failing AC fan motor is crucial to maintaining the performance and efficiency of your air conditioning system. The signs that a fan motor needs to be replaced have been mentioned above, It is recommended to hire a professional HVAC technician for the following steps:

Disconnect Power: Turn off the power supply to the AC unit by switching off the circuit breaker or disconnecting the power source.

Remove Access Panel: Open the access panel on the outdoor condensing unit where the fan motor is located. This may involve removing screws or loosening fasteners.

Disconnect Wiring: Carefully disconnect the wiring connections to the fan motor. Take note of the wire colors and connections for proper reinstallation.

Remove Fan Blade: Remove the fan blade from the motor shaft. This may require loosening a set screw or other fastening mechanism. Take care not to damage the blade or other components.

Remove Old Motor: Unscrew or unfasten the motor from its mounting bracket. Gently remove the old motor from the unit.

Install New Motor: Install the new fan motor in the same position as the old one. Secure it to the mounting bracket and ensure it is aligned properly.

Reattach Fan Blade: Place the fan blade back onto the motor shaft and secure it according to the manufacturer's instructions.

Connect Wiring: Reconnect the wiring connections to the new motor, ensuring the correct wire connections as noted earlier.

Test Operation: Before closing the access panel, turn on the power supply and test the operation of the new fan motor. Ensure it spins smoothly and without any unusual noises.

Close Access Panel: Once the motor is functioning correctly, close the access panel securely.

It's important to note that the specific steps and procedures may vary depending on the AC system and motor model. Always consult the manufacturer's instructions and, if unsure, seek professional assistance to ensure a proper and safe replacement.

The cost of AC fan motor replacement can vary depending on several factors, including the type of motor, its specifications, and the specific requirements of your AC system. Additionally, labor costs can vary based on location and the complexity of the replacement.

Given these factors, the cost of an AC fan motor replacement typically ranges from $200 to $800 or more. This range includes the cost of the motor and labor for installation. However, it's important to note that these figures are approximate, and actual costs can vary depending on the specifics of your situation.

To get an accurate estimate for AC fan motor replacement, it's recommended to contact local HVAC companies and provide them with the details of your AC system. They can provide you with a more precise cost estimate based on your specific requirements and the motor options available for your system.