In this article, we will look at motors, types of motors and how a motor controller works. We introduce the fundamentals of motors and motor controllers to help beginners kickstart their journey into the world of electromechanical systems. Motors are a crucial part of the modern world driving most of the equipment. Motors, pumps, fans, and even generators are motors working on reverse logic.

It is therefore necessary that the control of these devices is efficient and precise. These two important factors have always played an important role in all electronic design, more so in electric motors. The key to controlling motors is one, controlling the electricity needed to drive the motor and second eliminating the noise.

Motor controllers play a crucial role in controlling motor operation, allowing you to manage speed, direction, and other parameters.

Let’s have a look.

What is a Motor?

A motor is an electrically powered device that transfers electrical energy into mechanical energy. Most motors operate through the interaction between the magnetic field and electric current in the motor to generate torque on the shaft. Electric generators, on the other hand, operate on the mechanical principle, however in reverse, thus converting mechanical energy to electrical energy.

The motors produce a rotating motion that can be utilised to power various mechanical systems such as wheels, gears, or fans. There are various motor types, each designed for a specific application such as DC, AC, stepper, and servo motors.

DC Motors

These are the most common, and easiest to operate motors. A direct current (DC) motor is a type of electric motor that converts direct current electrical energy into mechanical energy. It generates motion by using magnetic fields. The magnetic field is formed by the stator, which is made up of a permanent magnet rotor and a rotating magnetic field stator. Magnets in low-power motors can be permanent (for example, ferrites), but magnets in medium- and high-power motors are generated by specific windings, also known as wound fields. Power is transferred to the rotor by rotating collectors and brushes.

Direct current (DC) motors are commonly used in robotics, toys, and tiny appliances.

AC Motors

In AC motors, mechanical energy is generated from magnetic fields that are generated through coils wrapped around the output shaft. The motion is obtained as the field induced in the rotor tries to catch up to the stator. The electromagnetic produced in the stator by the winding is always a step faster than the induced rotor magnetic field, creating the angular velocity difference. Unlike Direct Current motors, Alternating Current motors are generally brushless and thus do not need sliding contacts to operate.

Figure 1: AC Motor Winding

Alternating current (AC) motors are found in a variety of household equipment such as fans and air conditioners. They are classified as synchronous or asynchronous (induction) motors. The two differ in operational principle, characteristics and use.

- Synchronous AC motors

As implied in the name, synchronous motors have synchronized speeds between the rotor and the stator, thus the speed is constant and synchronized with the AC power supply frequency. This means the rotor of a synchronous motor rotates at the same speed as the rotating magnetic field generated by the power supply.

In these motors, the stator is supplied with alternating current to produce a rotating magnetic field around the rotor. On the other hand, the rotor is designed to generate its magnetic field, either using permanent magnets or an electromagnetic field from an external direct current power supply. They can either be separately excited or non-excited. The rotor and the stator are configured in such a way that the poles and the magnetic interaction are equal at the poles, such that when the motor is energized the fields get locked and the rotor and stator magnetic field rotate at the same speed.

It is important to note that due to inertia, synchronous motors need a starting torque from an additional winding, thus acting as an asynchronous motor during start-up. This means that they do not self-start.

These motors are ideal for applications that demand precise speed control. However, they require external means to initiate their operation and are typically more efficient at full load and near their synchronous speed. Synchronous motors find applications in devices like clocks, turntables, and power factor correction systems.

- Asynchronous (Induction) Motors

On the other hand, asynchronous motors, also known as induction motors, operate at a speed slightly lower than the synchronous speed. The rotor speed and the rotational speed of the stator magnetic field are not the same, with the rotor speed lagging. This is caused by a phenomenon commonly referred to as slip between the stator and rotor speed.

In construction, the rotor of the motor is either a squirrel cage or a wound-type rotor. The squirrel cage rotor is made of hefty copper bars that are joined at the ends by a conductive ring that electrically shorts them together. The wound-type rotor is constructed with several windings on top of a steel laminated core.

When energized, the stator rotational magnetic field induces current on the rotor which in turn generates a magnetic field. Due to the mutual induction, as stated in the Lenz law, the field generated by the rotor opposes the stator field and tries to eliminate it. Since the induced field on the coil can never be as fast as the stator, the speed of the motor is always slower than the synchronous speed and it depends on the slip of the motor.

One of its primary features is variable speed control, which can be accomplished by modifying the power supply's frequency or voltage or by using external control methods. Asynchronous motors are self-starting, making them easier to use, and they are extensively used in industrial machinery, domestic appliances (such as fans and washing machines), pumps, and conveyors. They are, nevertheless, less efficient than synchronous motors, especially at lower speeds.

Stepper motor

A stepper motor is a brushless DC motor that is characterized by its precision and accuracy. The moto moves in discrete steps which are achieved by driving a train of electric pulses applied at the excitation winding. The pulses can be used to define the shaft rotations step by step precisely. A single pulse generates a single step.

Figure 2: Stepper Motor

Stepper motors move in exact increments or steps, making them ideal for applications requiring accuracy and precise control of motion, such as 3D printers and CNC machines. Their simplicity and reliability make them very useful in automation systems. However, they are not known for their high torque or high speed.

Servo Motors

On the other hand, servo motors are a type of motors that offer precise and accurate control over position, speed and torque. Unlike stepper motors, servo motors offer more control of torque and speed. Control in servo motors is achieved through the use of a feedback mechanism, usually an encoder. The feedback is converted to an electrical signal that controls motion. Thus, servos can be taken as actuators that offer precise control over velocity, acceleration and linear and angular position.

Servo motors consist of four basic components; a DC motor, a position sensor, a gear drive/ gear train and a feedback control circuit. The position sensor works to provide the actual position of the motor and compares it to the desired position, thus providing feedback to the gear mechanism for precise adjustments.

Figure 3: A Servo Motor

As a result, servo motors excel in tasks where precision and accuracy are paramount, such as in industrial robotics, CNC machines, and camera gimbal systems.

It is important that although servo motors are operated by DC, there are AC servo motors that are operated by alternating current.

How to Control Motors

Controlling motors is one of the most important parts of using motors. One of the most common ways is controlling speed and direction. The mode of control used is determined by the mode of operation of the motor, the power used in the motor, circuits, and the type of motor and application. A motor controller aims to be able to act on an electric motor manually or automatically (start-stop, advance-inversion, speed, torsion, and voltage overload prevention).

There are several ways to control motors, let’s have a look.

Motor Controllers

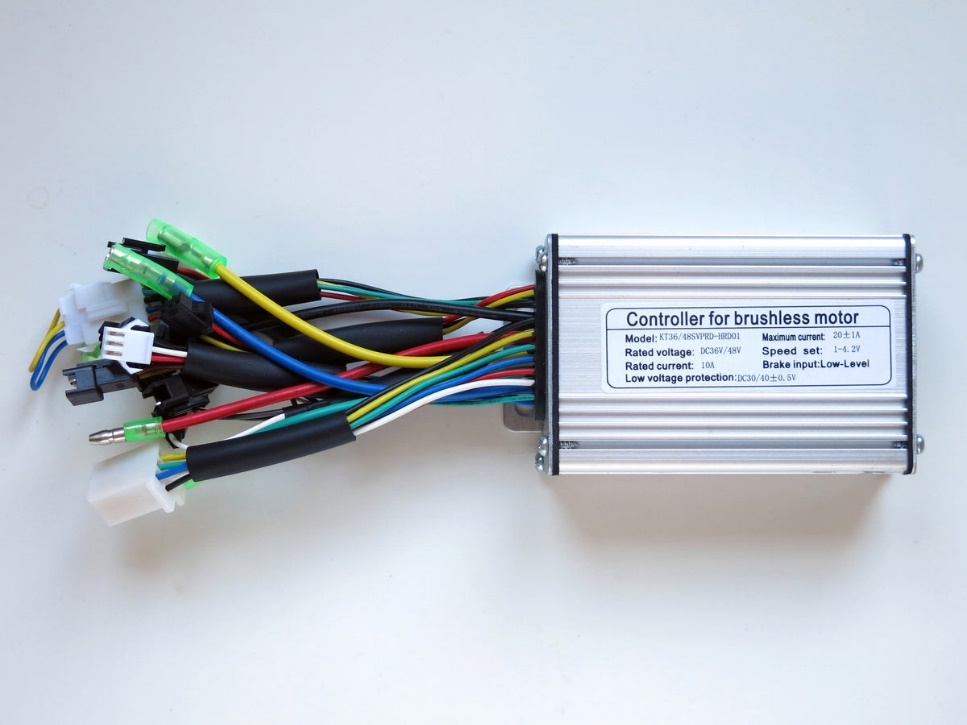

Motor controllers are electronic devices that allow you to control the speed, direction, and operation of motors. They play a crucial role in making motors usable in various applications. Generally, motor controllers receive power and provide signals to control the motors that they are connected to. By using special programs and circuits, one can control the starting, stopping, and running of motors. Here's an overview of a few known motor controllers:

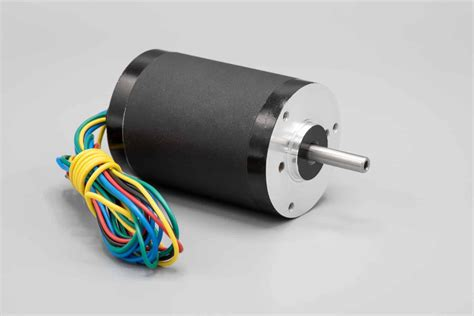

Figure 4: Sample Motor Controller

Types of Motor Controllers

- Motor Drivers:These are simple controllers used with DC motors. They provide basic speed and direction control, by adjusting the voltage and the polarity of the motor terminals in DC motors. In AC, the motor controllers designed for these motors adjust the amplitude and the frequency of the supply voltage. These are the two most widely used methods of controlling simple motor applications.

- H-Bridge Motor Drivers:H-bridge circuits are specialized controllers that are commonly used for controlling DC motors, enabling bi-directional control. They allow DC motors to run forward and backwards by changing the polarity of the supply voltage.

- Motor Shield/Module:These are plug-and-play boards that simplify motor control, often used with Arduino or Raspberry Pi.

- Microcontroller-Based Controllers:For more advanced control, you can use microcontrollers like Arduino or Raspberry Pi to program custom motor control algorithms. With controllers, it is possible to implement complex control algorithms and profiles. Microcontrollers can be used to design smart controllers that control power profiles that drive the motors. They can also be used to monitor the load on the motor and adjust the torque and speed depending on the motor load.

Figure 5: Microcontroller based Motor Drive

Application of Motor Controllers

Motor controllers offer several important functions and features to motors. Motor controllers are indispensable components for achieving precise control and automation in electromechanical systems. They come in various types, each tailored to specific motor types and applications, and offer a range of functions and features to meet diverse control requirements.

- Industrial automation and robotics

- CNC machines and 3D printers

- Electric vehicles and drones

- Household appliances (e.g., washing machines, fans)

- HVAC systems (heating, ventilation, and air conditioning)

- Aerospace and aviation

- Medical devices

- Consumer electronics (e.g., camera gimbals)

Conclusion

Finally, motor controllers are critical components that enable accurate control of many types of motors, such as DC, AC, servo, and stepper motors. They provide capabilities like as speed control, direction control, torque adjustment, and feedback integration, making them indispensable in a wide range of applications, from industrial automation and robotics to household appliances and automotive systems. The motor controller chosen is determined by the motor type, control interface, and unique application requirements. Understanding motor controller capabilities and characteristics is critical for efficiently applying them in electromechanical systems, boosting precision, efficiency, and automation in a variety of sectors.