Table of Contents

- 1.0 The Unseen Engine of Modern Vehicles

- 2.0 What Are Automotive-Grade ICs?

- 2.1 Defining the Standard: Beyond Commercial Grade

- 2.2 Market Positioning and Key Players

- 3.0 The Core Specifications: Understanding AEC-Q100

- 3.1 AEC-Q100 Temperature Grades

- 3.2 Rigorous Stress Testing

- 4.0 Deep Dive: A Comprehensive Review of Automotive ICs

- 4.1 Design and Packaging

- 4.2 Core Functions and Applications

- 4.3 Performance in Harsh Environments

- 5.0 Automotive vs. Commercial ICs: A Head-to-Head Comparison

- 6.0 Advantages and Disadvantages

- 6.1 The Top 5 Advantages

- 6.2 Potential Drawbacks

- 7.0 How to Choose the Right Automotive-Grade IC

- 8.0 Frequently Asked Questions (FAQ)

- 9.0 Conclusion: The Future is Automotive-Grade

1.0 The Unseen Engine of Modern Vehicles

Have you ever wondered what powers the sophisticated safety systems, brilliant infotainment displays, and seamless connectivity in your car? The answer lies hidden within a complex network of tiny, powerful components: automotive-grade ICs. As vehicles evolve into rolling data centers, the demand for electronics that can withstand the brutal automotive environment has never been higher. Yet, selecting the right components that guarantee safety and longevity can be a daunting task for even seasoned engineers.

Did you know that electronics are projected to make up around 50% of a new car’s cost by 2030? This incredible growth highlights the critical role of specialized components. This guide provides a comprehensive review of automotive-grade ICs, from the rigorous AEC-Q100 qualification standards to their real-world applications. We will explore their core specifications, compare them to commercial-grade counterparts, and offer a clear roadmap for choosing the perfect IC for your next project. Get ready to dive deep into the world of automotive electronics and discover what it takes to build the vehicles of tomorrow.

2.0 What Are Automotive-Grade ICs?

At its core, an automotive-grade integrated circuit (IC) is a semiconductor component specifically designed, manufactured, and tested to meet the stringent demands of the automotive environment. Unlike their commercial-grade counterparts found in consumer electronics, these ICs are built for extreme reliability, longevity, and performance under harsh conditions. They are the bedrock of nearly every electronic system in a modern vehicle, from engine management and safety-critical functions to in-cabin comfort and infotainment.

2.1 Defining the Standard: Beyond Commercial Grade

The fundamental difference between automotive and commercial ICs lies in their qualification process and operational resilience. Automotive components must endure a much wider range of operating temperatures, from a frigid -40°C in a winter cold start to a blistering 150°C in an engine compartment. They are also subjected to constant vibration, mechanical shock, and humidity for a lifespan that often exceeds 15 years.

Pro Tip: When selecting components, always look for the AEC-Q100 qualification. This is the industry-wide stamp of approval that certifies an IC has passed a battery of stress tests and is ready for the rigors of the road.

This level of robustness is non-negotiable. A failure in a consumer device might be an inconvenience, but a failure in an automotive-grade IC could have critical safety implications, such as a malfunction in the airbag deployment system or the anti-lock brakes. Therefore, these components are governed by strict industry standards like AEC-Q100, ISO 26262 for functional safety, and IATF 16949 for quality management.

2.2 Market Positioning and Key Players

The automotive IC market is a highly competitive and rapidly growing sector. The global market size is expected to reach USD 116.60 billion in 2025 and is projected to grow to USD 189.80 billion by 2030, with a compound annual growth rate (CAGR) of 10.24% [1]. This growth is fueled by the increasing electronic content per vehicle, driven by trends like electrification, autonomous driving, and connected car technologies.

Several semiconductor giants dominate this space, each with its own areas of specialization. The top five manufacturers alone command over 50% of the market share.

| Manufacturer | Headquarters | Key Strengths | 2023 Market Share (Approx.) |

|---|---|---|---|

| Infineon Technologies | Germany | Market leader, strong in microcontrollers and power semiconductors | ~13% |

| NXP Semiconductors | Netherlands | Leader in automotive microcontrollers and communication ICs | ~11% |

| STMicroelectronics | Switzerland | Broad portfolio of automotive ICs, including ADAS and MCUs | ~9% |

| Texas Instruments | USA | Strong in analog and power management ICs | ~8.5% |

| Renesas Electronics | Japan | Leading provider of automotive microcontrollers and SoCs | ~6.7% |

3.0 The Core Specifications: Understanding AEC-Q100

When you see the AEC-Q100 label on an integrated circuit, it signifies more than just a quality check; it’s a testament to its resilience. As the industry benchmark for automotive ICs, the AEC-Q100 standard, established by the Automotive Electronics Council, outlines a series of rigorous stress tests designed to ensure components can survive the demanding conditions within a vehicle for their entire service life. Understanding this standard is crucial for anyone involved in designing or sourcing automotive electronics.

3.1 AEC-Q100 Temperature Grades

One of the most critical aspects of the AEC-Q100 standard is the classification of components into different temperature grades. This ensures that you can select an IC that is perfectly matched to the thermal environment of its specific application. A sensor in the engine bay faces a much harsher reality than a chip in the cabin’s infotainment system. Have you ever considered how temperature swings can affect electronic performance?

Here’s a breakdown of the standard AEC-Q100 temperature grades:

- Grade 0: -40°C to 150°C (Engine compartment and other extreme heat zones)

- Grade 1: -40°C to 125°C (Most under-the-hood applications)

- Grade 2: -40°C to 105°C (Passenger compartment, high-temperature areas)

- Grade 3: -40°C to 85°C (Most passenger compartment applications)

Important Note: Selecting the correct temperature grade is not just about preventing failure; it’s about ensuring consistent performance and reliability over the long term. Using an underrated component can lead to premature aging and unexpected malfunctions down the road.

3.2 Rigorous Stress Testing

The AEC-Q100 qualification is not a single test but a comprehensive suite of stress tests that simulate the life cycle of a component in an automotive environment. These tests are designed to accelerate potential failure mechanisms, revealing any weaknesses in the IC’s design, packaging, or manufacturing process.

According to the Automotive Electronics Council, AEC-Q100 is a “failure mechanism-based stress test qualification for integrated circuits.” This approach proactively targets known weaknesses in semiconductor devices.

Key stress tests include:

- Accelerated Environment Stress: Tests like Temperature Cycling (TC), High-Temperature Storage (HTSL), and Power Temperature Cycling (PTC) push the component to its thermal limits.

- Accelerated Lifetime Simulation: Tests such as High-Temperature Operating Life (HTOL) simulate years of operation in a compressed timeframe.

- Package Assembly Integrity: Tests like Solder Heat Resistance (SHR) and Physical Dimensions (PD) ensure the IC’s package can withstand manufacturing processes and maintain its structural integrity.

- Electrical Verification: Tests like Electrostatic Discharge (ESD) ensure the IC can survive static shocks during handling and operation.

Passing these tests is a mandatory gateway for any IC aspiring to be considered automotive-grade. It’s this grueling process that gives engineers the confidence to place these components at the heart of safety-critical systems.

4.0 Deep Dive: A Comprehensive Review of Automotive ICs

Now that we’ve established the rigorous standards that define automotive-grade ICs, let’s take a closer look at what makes them tick. From their physical construction to their diverse roles within the vehicle, these components are marvels of modern engineering. This section provides a detailed review of their design, core functions, and performance under the demanding conditions they face daily.

4.1 Design and Packaging

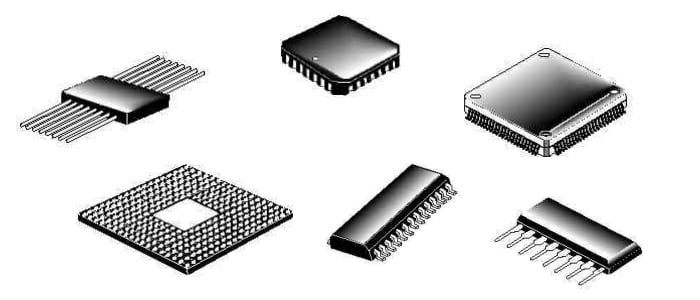

The design of an automotive IC goes far beyond the silicon itself. The packaging plays a critical role in protecting the delicate circuitry from the harsh automotive environment. Materials are carefully selected for their thermal properties, durability, and resistance to moisture and chemicals. You’ll often find robust package types like Quad Flat Package (QFP) and Ball Grid Array (BGA) with specific modifications to enhance reliability.

For instance, many automotive ICs feature wettable flanks on their lead-less packages. This design allows for automated optical inspection (AOI) of solder joints, a crucial step in ensuring manufacturing quality and long-term reliability. It’s a small detail that makes a huge difference in preventing connection failures over the vehicle’s lifespan.

A variety of package types are used for automotive-grade ICs to ensure reliability. Source: All About Circuits

4.2 Core Functions and Applications

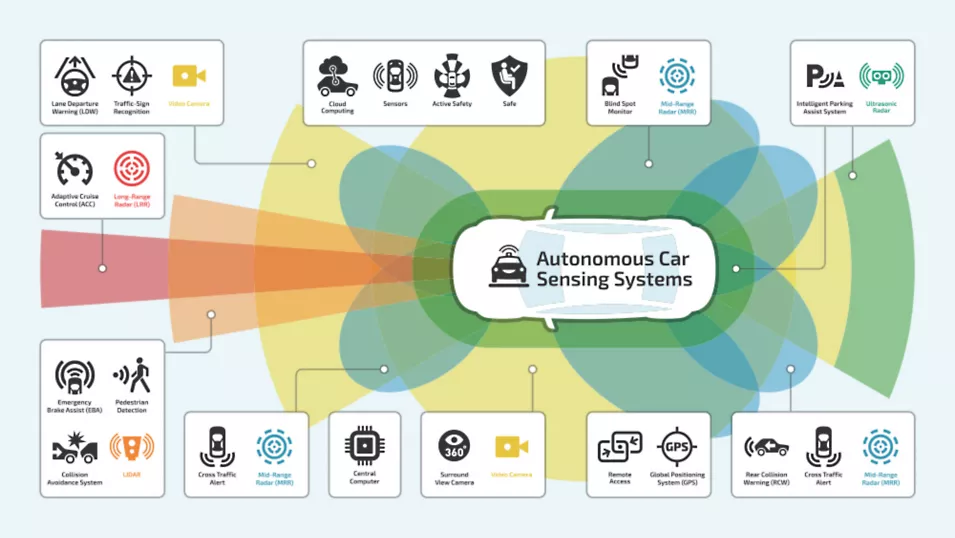

Automotive ICs are the workhorses of the vehicle’s electronic architecture. They can be broadly categorized based on their function. Are you familiar with the sheer breadth of their applications?

- Microcontrollers (MCUs): These are the “brains” of many systems, executing code to control everything from the engine and transmission (powertrain control) to the windows and seats (body electronics).

- Sensor ICs: The “senses” of the vehicle, converting physical measurements like pressure, temperature, and acceleration into electrical signals for systems like TPMS and ADAS.

- Power Management ICs (PMICs): The “heart” of the power distribution network, ensuring all components receive a stable and efficient supply of electricity. This is especially critical in electric vehicles (EVs).

- Communication ICs: The “nervous system,” facilitating communication between different electronic control units (ECUs) via protocols like CAN, LIN, and automotive Ethernet.

- Memory ICs: Providing the necessary data storage for everything from firmware and operational parameters to user settings in the infotainment system.

4.3 Performance in Harsh Environments

This is where automotive-grade ICs truly shine. Their ability to perform flawlessly under extreme conditions is a direct result of their robust design and the rigorous AEC-Q100 qualification process.

Consider a typical engine control unit (ECU). It’s bolted to an engine block that vibrates constantly and can reach temperatures well over 100°C. Yet, the MCU inside must execute millions of instructions per second without error to keep the engine running efficiently and safely. This is achieved through a combination of factors:

- Wider Operating Margins: Automotive ICs are designed with larger voltage and temperature margins than their commercial counterparts.

- Robust Materials: The lead frames, bond wires, and molding compounds are all selected to withstand thermal stress and vibration.

- Advanced Thermal Management: Many high-power automotive ICs incorporate features like exposed pads to efficiently dissipate heat.

This unwavering performance is not a luxury; it’s a fundamental requirement for the safety and reliability of modern vehicles.

5.0 Automotive vs. Commercial ICs: A Head-to-Head Comparison

To truly appreciate the engineering that goes into automotive-grade ICs, it’s helpful to compare them directly with their commercial-grade counterparts. While both may perform similar functions on a datasheet, their design philosophies, manufacturing processes, and reliability targets are worlds apart. What exactly separates a chip destined for a car from one designed for a smartphone?

This head-to-head comparison highlights the key differentiators that every engineer and purchasing manager should understand.

| Feature | Automotive-Grade ICs | Commercial-Grade ICs |

|---|---|---|

| Temperature Range | -40°C to 150°C (Grades 0-3) | 0°C to 70°C (Standard) |

| Qualification | AEC-Q100, ISO 26262, IATF 16949 | JEDEC standards |

| Target Failure Rate | Near-zero defects (typically <1 PPM) | Higher PPM (Parts Per Million) rates are acceptable |

| Lifespan | 10-15 years | 2-5 years |

| Cost | Higher due to rigorous testing and robust materials | Lower, optimized for high-volume consumer markets |

| Traceability | Fuljakelectronics.com/productdetail/feigelectronic-360500000-1770567">electronics.com/">jakelectronics.com/productdetail/sgmicro-sgm809xxn3tr-20982402">www.jakelectronics.com/productdetail/maxlinearinc-sp1485ecnltr-6186851">l traceability from wafer to final product | Limited or no traceability |

Editor’s Take: I once worked on a project where a team tried to substitute a commercial-grade power IC into an automotive design to save costs. The component passed initial bench tests but failed catastrophically during temperature cycling. The failure analysis revealed micro-fractures in the package that wouldn’t have occurred in a properly qualified automotive-grade part. It was a costly lesson in not cutting corners where reliability is paramount.

The bottom line is that while a commercial IC is designed for a controlled environment and a limited lifespan, an automotive IC is engineered to survive a decade or more of abuse. The higher upfront cost of automotive-grade components is an investment in safety, reliability, and the long-term integrity of the vehicle.

Automotive ICs are held to a much higher standard of reliability and durability. Source: Ansys

6.0 Advantages and Disadvantages

While the benefits of using automotive-grade ICs in vehicle systems are clear, it’s important to have a balanced view. Like any specialized component, they come with a unique set of trade-offs. Understanding both the pros and cons is essential for making informed design and sourcing decisions. Is the added cost always justified? Let’s break it down.

6.1 The Top 5 Advantages

Opting for automotive-grade components brings a host of benefits that are critical for the reliability and safety of any vehicle.

- Unmatched Reliability: The single biggest advantage is their extremely low failure rate. The rigorous AEC-Q100 qualification process weeds out components that can’t handle long-term stress, resulting in a level of reliability that commercial-grade parts simply cannot match.

- Enhanced Safety: In an industry where malfunctions can have life-or-death consequences, the safety assurance provided by automotive-grade ICs is paramount. Compliance with standards like ISO 26262 ensures that functional safety is baked into the component’s design.

- Long-Term Durability: These components are built to last the entire lifespan of a vehicle, often 15 years or more. This longevity reduces the likelihood of costly electronic repairs for the vehicle owner and protects the manufacturer’s brand reputation.

- Superior Performance in Harsh Conditions: From extreme temperatures to constant vibrations, automotive ICs are engineered to maintain stable performance. This ensures that systems like ADAS and engine management function correctly, regardless of the external environment.

- Guaranteed Traceability and Quality: The automotive supply chain demands strict traceability. Every automotive-grade IC can be traced back to its production batch, providing an essential layer of quality control and accountability that is often missing in the commercial market.

6.2 Potential Drawbacks

Despite their clear advantages, there are a few trade-offs to consider when working with automotive-grade ICs.

- Higher Cost: The robust materials, extensive testing, and rigorous qualification processes all add to the cost. An automotive-grade IC can be significantly more expensive than its commercial equivalent.

- Slower Adoption of Cutting-Edge Technology: The automotive industry is famously cautious. The long qualification cycles (often 2-3 years) mean that the latest and greatest semiconductor technology takes longer to appear in automotive-grade versions compared to the fast-paced consumer electronics market.

- Limited Availability and Longer Lead Times: The specialized nature of these components can sometimes lead to longer lead times and more limited sourcing options compared to high-volume commercial parts. This requires more careful supply chain management.

Important Note: While the upfront cost is higher, the total cost of ownership for an automotive-grade IC is often lower. Factoring in the potential costs of recalls, warranty claims, and reputational damage from using less reliable components makes the initial investment a wise one.

7.0 How to Choose the Right Automotive-Grade IC

Selecting the perfect automotive-grade IC from a sea of options can feel overwhelming. The right choice ensures your design is reliable, safe, and cost-effective, while the wrong one can lead to costly redesigns and potential field failures. So, how do you navigate this critical decision? This section provides a practical checklist to guide you through the selection process.

Your Automotive IC Selection Checklist

- Define Your Application’s Environment:

- What is the mission profile? First, pinpoint exactly where the IC will live. Is it in the relative comfort of the passenger cabin, or is it bolted to the engine block?

- Determine the Temperature Grade: Based on the location, select the appropriate AEC-Q100 temperature grade. Don’t over-specify (which adds unnecessary cost) or under-spec-ify (which risks failure). Grade 1 (-40°C to 125°C) is a common choice for many robust applications, but always verify your specific needs.

- Verify Functional Safety Requirements:

- Is the function safety-critical? If the IC is part of a system that could impact driver or passenger safety (e.g., braking, steering, airbag control), it must comply with ISO 26262.

- Check the ASIL Rating: Determine the required Automotive Safety Integrity Level (ASIL). ASIL D is the highest level for the most critical applications, while ASIL B might be sufficient for others. Ensure the component’s documentation supports the required ASIL level.

- Scrutinize the Supplier’s Reputation and Support:

- Choose Tier 1 Suppliers: Stick with established manufacturers like Infineon, NXP, STMicroelectronics, Texas Instruments, and Renesas. These companies have a proven track record in the automotive industry.

- Evaluate Long-Term Availability: The automotive lifecycle is long. Ensure the supplier has a longevity program that guarantees the part will be available for 10-15 years, avoiding costly redesigns due to obsolescence.

- Review Documentation and Support: High-quality, comprehensive documentation is a must. Good technical support from the manufacturer can save you countless hours during the design and debugging phases.

- Plan for the Entire Lifecycle:

- Consider PPAP: The Production Part Approval Process (PPAP) is a cornerstone of automotive quality. Ensure your supplier can provide all necessary PPAP documentation.

- Think About Software: For complex components like microcontrollers and SoCs, consider the software ecosystem. Are the development tools mature? Is there a robust library of drivers and middleware available?

Pro Tip: Don’t just rely on the datasheet. Request the AEC-Q100 qualification report and the functional safety certificate. This documentation provides the concrete evidence you need to be confident in your component choice. A reputable supplier will always provide this on request.

8.0 Frequently Asked Questions (FAQ)

Navigating the specifics of automotive-grade ICs can bring up a lot of questions. Here are answers to some of the most common queries we encounter from engineers and designers.

What is the main difference between AEC-Q100 and AEC-Q200?

The primary difference lies in the type of components they cover. AEC-Q100 is the stress test qualification standard specifically for integrated circuits (ICs). In contrast, AEC-Q200 is the standard for passive electronic components, such as resistors, capacitors, and inductors. While both ensure components are fit for automotive use, they target different categories of electronics.

Can I use a commercial-grade IC in a non-safety-critical automotive application?

While it might seem tempting for a non-critical function like an interior dome light, it is strongly discouraged. The automotive environment—with its extreme temperatures, vibrations, and electrical noise—can cause even a non-critical commercial component to fail prematurely. This can lead to warranty claims and a negative perception of your product’s quality. Sticking with a low-temperature grade (like Grade 3) automotive-grade IC is always the safer and more reliable choice.

How does the rise of electric vehicles (EVs) impact the automotive IC market?

The shift to EVs is a massive catalyst for the automotive IC market. EVs have a significantly higher semiconductor content than traditional internal combustion engine (ICE) vehicles. They require sophisticated Power Management ICs (PMICs) for battery management systems (BMS), high-power inverters, and onboard chargers. The demand for advanced microcontrollers and sensor ICs for powertrain control and efficiency optimization is also exploding.

What does ASIL mean in the context of automotive ICs?

ASIL stands for Automotive Safety Integrity Level. It is a risk classification scheme defined by the ISO 26262 functional safety standard. ASIL is determined based on the severity, exposure, and controllability of a potential hazard if a system fails. There are four levels, from ASIL A (lowest risk) to ASIL D (highest risk). An IC intended for a safety-critical system, like an airbag controller, must be certified to the appropriate ASIL level.

Are all automotive-grade ICs from major brands of similar quality?

While all reputable manufacturers adhere to the AEC-Q100 standard, there can be differences in manufacturing processes, material quality, and design robustness. Leading suppliers like Infineon and NXP often have decades of experience and highly mature automotive production lines. It’s always wise to review the supplier’s qualification data and reliability reports. Sometimes, a supplier may have a specific strength in a particular type of IC, such as analog or power devices.

9.0 Conclusion: The Future is Automotive-Grade

The journey through the world of automotive-grade ICs reveals a landscape where reliability is not just a feature, but the very foundation. From the rigorous trials of AEC-Q100 to the meticulous design considerations for functional safety, these components are engineered to a standard far beyond their commercial cousins. As vehicles become more autonomous, connected, and electrified, the role of these powerful, resilient chips will only become more critical. The projected growth of the market to USD 189.80 billion by 2030 is a clear indicator of this unstoppable trend.

Choosing the right automotive-grade IC is a decision that balances performance, cost, and, most importantly, safety. By understanding the standards, knowing the key players, and following a diligent selection process, you can build electronic systems that are not only innovative but also incredibly robust. The future of mobility depends on the unseen heroes of the automotive world—the humble yet powerful integrated circuits that work tirelessly to keep us safe on the road.

Ready to take the next step in your automotive design journey? Explore our extensive portfolio of automotive-grade ICs and find the perfect components to power your innovation. Let us help you build the future of transportation, one reliable chip at a time.

Last Updated: October 21, 2025

References

[1] Mordor Intelligence. (2025). Automotive Integrated Circuits Market Size & Share Analysis. Retrieved from https://www.mordorintelligence.com/industry-reports/automotive-integrated-circuits-market

[2] Altium. (2025). Component Standards for Automotive Grade Electronics. Retrieved from https://resources.altium.com/p/component-standards-automotive-grade-electronics

[3] Kruse, F. (n.d.). Essential Guide to Automotive ICs: Types and Applications. Retrieved from https://kruse.de/automotive-ic-2/