Cranes, lifts, elevators, turbines and electric vehicles including trains that use motors, require accurate and precise speed control. To achieve accurate speed control, it is important to have both control acceleration and deceleration, that is braking. Electric motors thus use resistor -and-its-function>jakelectronics .com/blog/what-is- resistor -and-its-function>jakelectronics .com/blog/what-is- resistor -and-its-function>jakelectronics .com/blog/what-are-braking- stm32h753xih6 -4813125>stm32h753xih6 -4813125> resistors > braking resistors , since they are the most common and effective high-power resistors to control the motor speed. Their applications are vast from the transportation industry, construction and even plant robotics with fast but precise operations.

To understand the purpose of a braking resistor , it is important to understand how a motor works during acceleration and deceleration. A motor can act as a generator. When the motor is in the accelerating phase, it consumes energy from the reserve battery and moves the shafts or wheels. Consequently, the inverse is also true when decelerating. In the braking phase, also known as regenerative braking, or when the motor is freewheeled due to momentum or inertia forces, it generates energy. This energy is fed back to the power supply or can be stored.

On the other hand, if not properly managed or controlled back emf, the energy during decelerating can be destructive to the system. A braking resistor is thus used to protect the system from numerous drive trips brought on by overvoltage, shortened equipment life or expensive maintenance expenses, or damaged motors and drives from overheating.

One of the properties of a resistor is that resistors can be used to dissipate heat, this can be used in mechanical systems through a process of dynamic braking. The resistor used in this process is thus referred to as a dynamic resistor, or brake resistor for short. Kinetic energy is converted back into electrical energy to slow down an electric motor. With the use of a power resistor, this energy can be dumped into the body of the system. Rheostatic and regenerative dynamic braking are the two common ways that are used to decelerate running motors. The energy lost during rheostatic braking is converted to heat in a resistor. The electric power is recycled back into the system during regenerative braking.

What is a electronics.com/productdetail/sgmicro-sgm809xxn3tr-20982402">www.jakelectronics.com/blog/what-are-braking-resistors">braking resistor?

Braking resistors also known as dynamic braking resistors are electrical components that are used in electrical circuits to absorb extra energy and heat produced during an electric motor's braking. To reduce or halt the speed of a mechanical system, it produces a braking torque. They are frequently employed in machines like cranes, elevators, and trains where the motor must instantly stop or decelerate.

Brake resistors are usually designed with a relatively low ohmic value and a very high power rating. This specification helps in controlling the motor by dissipating the energy in the form of heat. A wire-wound resistor is common and is thus the most preferred design for braking resistors. They are entirely welded and frequently feature a ceramic core. To ensure a secure separation from other components, they are often enclosed in a frame. The frames frequently come with cooling fins, fans, or even water cooling to boost their capacity for power dissipation.

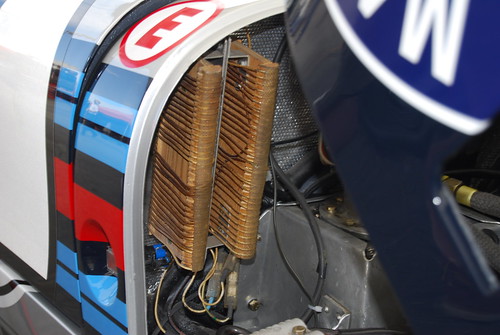

Figure 1: A sample of a brake resistor

How a braking resistor works?

When an electric motor is powered, it generates kinetic energy, which is used to perform work. When the motor is stopped or decelerated, this kinetic energy is converted into electrical energy, which can cause the motor to act as a generator. This can result in an excess of electrical energy that needs to be dissipated to prevent damage to the motor or other components in the circuit.

Figure 2: A braking resistor installed in a car

A braking resistor is connected in parallel with the motor and is designed to absorb this excess energy by converting it into heat. The resistor is typically made of a material with high resistance to electrical currents, such as ceramic or wire-wound metal, which allows it to generate a significant amount of heat.

The brake resistor works to swiftly and safely slow down the motor while shielding other parts of the circuit from overvoltage-related harm by dissipating the extra energy as heat. Depending on the individual application and the required quantity of energy dissipation, there are several sizes and ratings of braking resistors.

Types of Brake resistors>Resistors

As mentioned earlier, the choice of braking resistor specifications depends on the type of application and the environment in which it is used. Thus, there are several types of braking resistors, with the most commonly used being wire-wound resistors. Here are some of the commonly used types of braking resistors and their application advantages:

- Wire-wound resistors

These are a common choice for applications that require high power dissipation, as they can handle large amounts of energy and have good temperature stability. They are often used in industrial applications, such as elevators and cranes, where heavy loads are being lifted and need to be stopped quickly.

- Ceramic resistors

These are a good choice for applications that require a small and lightweight braking resistor, as they have a low profile and can be mounted directly onto a circuit board. They are often used in electronic equipment, such as power supplies and motor control circuits.

- Metal oxide resistors

These are a good choice for applications that require high stability and reliability, as they have a high tolerance for harsh operating environments, including high temperatures and humidity. They are often used in industrial equipment, such as oil rigs and mining machinery.

- Film resistors

These are a good choice for applications that require precise resistance values, as they can be manufactured with high accuracy and low tolerance levels. They are often used in precision measurement equipment, such as medical devices and scientific instruments.

When selecting the type of resistor for use in a certain system or for use in a particular application, it is important to consider the specific requirements as well as the material of the resistor , the amount of energy to be dissipated, the environment of operation as well as weight and size requirements. Choosing the right braking resistor is critical to ensure optimal performance and safety of the electrical circuit.

Factors to consider when selecting a braking resistor other than the type of resistor include power rating, voltage rating, resistance value, temperature rating, environmental factors, and size/weight constraints. A braking resistor with a higher power rating can handle more energy, while a voltage rating that is too low or high can cause damage to the resistor or other components in the circuit. Consider the physical constraints of the application, such as space limitations or weight restrictions, and choose a braking resistor that is compatible with the overall design of the electrical circuit. Consult with a qualified electrical engineer or technician to ensure that the braking resistor is properly matched to the specific requirements of the application.

Resistance braking vs Frictional braking

Frictional braking is the traditional approach to braking, in which mechanical braking is achieved using brake pads, or contact with moving parts, thus decelerating the moving part. Generally, it involves any methods that use friction to achieve a braking system.

Figure 3: A Friction Braking System using a Brake Pad

Motors and other machinery can be slowed down or stopped using either frictional braking or resistance braking. Here are some benefits of resistance braking versus frictional braking:

- Precision: Resistance braking is a superior option for situations that need exact stopping or holding because it may offer more precise control over the amount of energy being wasted.

- Reduced wear and tear: Compared to frictional braking, resistance braking puts less strain on the brake system. This is because frictional braking depends on the physical contact of two surfaces, which over time can produce heat and lead to wear and tear.

- Efficiency: Compared to frictional braking, resistance braking is often more effective in converting energy into usable forms rather than letting it escape as heat. Less energy use and money can be saved as a result of this.

- Quieter operation: Resistance braking is a superior option for situations where noise is an issue, such as in residential or commercial buildings because it does not make as much noise as frictional braking.

- Reduced maintenance: Because there are no physical components that need to be replaced or repaired as a result of wear and tear, resistance braking requires less maintenance than frictional braking.

However, based on the fact that braking resistors and the resistance braking systems works on the principle of dissipating off kinetic energy as heat when not properly cooled the braking resistors can degrade over time quickly and fail prematurely.

Maintenance and Best Practices for Braking Resistors

Like all other components in cars, automotive and all mechanical and electrical systems it is important to perform regular checks and inspections for both reactive and preventive maintenance. Here are some common maintenance and best practice tips for braking resistors:

- Inspection: Braking resistors should be tested frequently to make sure they are in excellent shape and unharmed by physical defects like corrosion or fractures. Replace any worn-out or broken resistors right away to avoid any safety risks.

- Cleaning: Over time, dust and other debris can build up on braking resistors and impact how well they work. The resistors should be cleaned often with a soft brush or compressed air to get rid of any dust or debris that may have built up on the surface.

- Testing: Testing brake resistors regularly might assist find possible problems before they become serious ones. The resistor's resistance may be measured through tests with a multimeter to make sure it is operating within the required parameters.

- Temperature monitoring: Monitoring of temperature is necessary to prevent overheating of the braking resistors since they produce heat while they are in use. Temperature sensors can be fitted to keep track of the resistor's temperature and notify maintenance staff if it rises over the acceptable working range.

- Replacement: Braking resistors may eventually wear out and need to be replaced. The same kind of resistor that is compatible with the electrical circuit and satisfies the requirements should be used to replace them.