With developments in the field of IoT and big data analytics, a large amount of data is available to feed AI algorithms to monitor power electronics in various phases of their life cycle. The increasing volume of data lays a solid foundation for the development of AI in power electronics.

With the invention of mercury-arc valves in the early 1900s, power electronics was considered to be a revolution in itself because of the numerous applications it could serve in the industry. With the introduction of semiconductor devices like bipolar junction transistors, the market segment witnessed improved power efficiency and enhanced performance along with reduced manufacturing costs for power-electronic systems. Slowly, there have been technological advancements in semiconductor-based power devices with the integration of artificial intelligence in the complete power-electronic system.

Be it generation or transmission, power electronics are present in almost every industrial automation application. Renewable energy generation, high-voltage direct-current power transmission, flexible AC transmission systems, electric vehicles, and microgrids are some of the widespread applications possible because of semiconductor-based power devices. But as the industry evolves, the need for more efficient manufacturing, control, and maintenance of these components has increased. Semiconductor-based power devices are high-frequency devices operating at high switching frequencies; hence, control of these devices is a cumbersome task. One such example are silicon carbide–based JFETs and MOSFETs. AI has proven to be an efficient approach to designing, controlling, and maintaining power-electronic devices with utmost efficiency.

Intelligence is no longer a human trait. With Industry 3.0 leaving a dire need for automation and intelligent systems, AI and machine learning have become the foundation of Industry 4.0. The aim of AI is to facilitate machines to demonstrate human-like thinking and intelligence without getting tired like humans. AI finds applications in fields like facial recognition, autonomous vehicles, speech recognition, chatbots, and more.

Due to specific challenges like high tuning speed and high sensitivity in condition monitoring, AI has specific implementation advantages in power electronics. AI has applications in three life-cycle phases for power electronics: design, control, and maintenance.

With developments in the field of IoT and big data analytics, a large amount of data is available to feed AI algorithms to monitor power electronics in various phases of their life cycle. The increasing volume of data lays a solid foundation for the development of AI in power electronics. AI is able to exploit data to improve product competitiveness by global design optimization, intelligent control, and system health status estimation. As a result, research in power electronics can be conducted from a data-driven perspective, which is beneficial, especially in complex and challenging use cases.

Function and methods of AI in power electronics

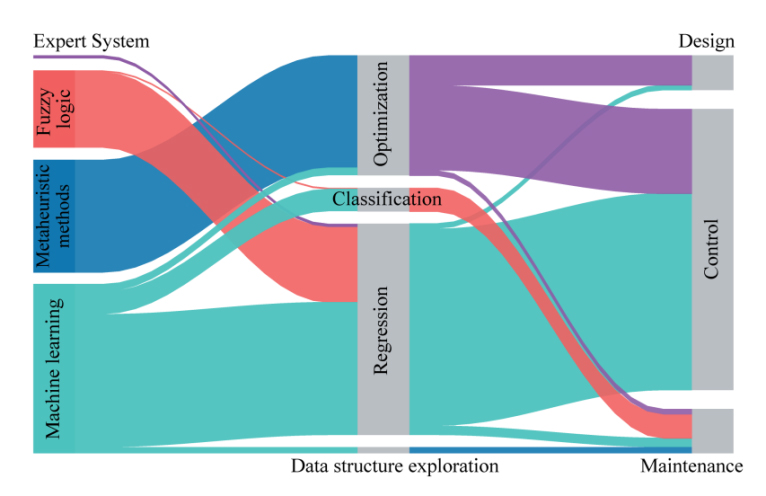

The application of AI in power electronics is most significant during the control phase, followed by the maintenance phase, and is least impactful during the design phase. The AI functions used can be primarily categorized as optimization, classification, regression, and data structure exploration. However, the majority of the tasks are regression and optimization.

The widely used AI methods in power electronics can be generally categorized as expert systems, fuzzy logic, metaheuristic methods, and machine learning. ML forms the majority in the case of power-electronic applications. For application in power electronics, ML is further classified as supervised learning, unsupervised learning, and reinforced learning.

Today, the application of both expert systems and fuzzy logic is moderate, especially for expert systems, as with the development of more powerful computing machines, more sophisticated AI tools are taken into practice. Metaheuristic methods are continuously evolving and applied to power electronics. They are used for a complete task or jointly with other ML methods. Reinforcement learning is the latest frontier of the ML methods applied to power electronics, facilitated by the rapid development of computing hardware.

Future scope of AI in power electronics

Although there has been a lot of surveys and research on the potential application of AI in power electronics, it has not yet achieved the potential it claims to have. Deeper investigations and research are necessary to utilize the complete power of the data to train models for AI.

There are different reasons why industries hesitate to implement AI, including:

- Implementation complexity

- Doubt about algorithm robustness and accuracy

- Extra hardware cost

- Huge computational energy consumption

Another bottleneck in the implementation of AI in power electronics is the lack of availability of extensive datasets to train models. Making these datasets is a resource-consuming task, and when it comes to safety-critical tasks, the available data is even less. Thus, it is necessary to develop a data-light AI solution that can provide desired solutions with less training data.

There is also a pressing need to make explainable AI algorithms that can convince practitioners to implement them in safety-critical applications. Understanding how the model works would help improve upon its features for the desired implementation. With the world gearing up for Industry 4.0, AI and ML have proven to be its foundation. Power electronics and AI are two very strong pieces of technology that could bring forward a revolution. Although there are bottlenecks to implementing AI with power electronics, with extensive research, it should not be a far-fetched dream.